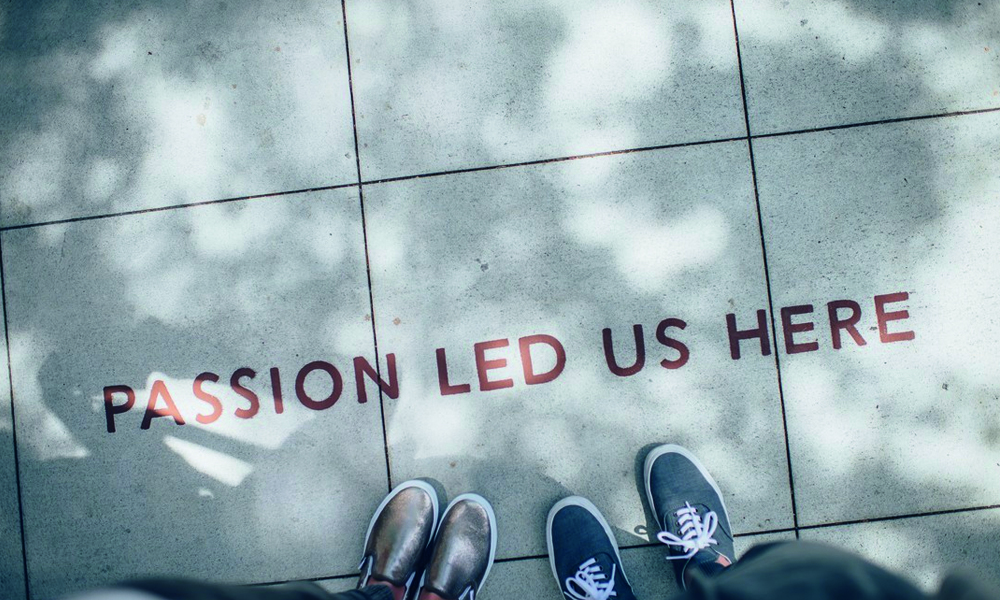

Passion & customer-centricity – A decisive factor to success

As 2018 is coming to an end, I have used the festive season to reflect on what we at AS-Schneider have achieved over the course of the year. Very often we forget to celebrate our success and tend to focus on the challenges (and there are plenty). From the sales point of view, I’m extremely happy to celebrate one of the best years in our 143-year-long history.