5 important facts for a safe and transparent (remote) third-party inspection

We are all facing many restrictions due to the pandemic. Therefore, we need to find ways to still provide the best possible support to our customers. One digital service that our customers can use is our third party inspections – better said remote inspections.

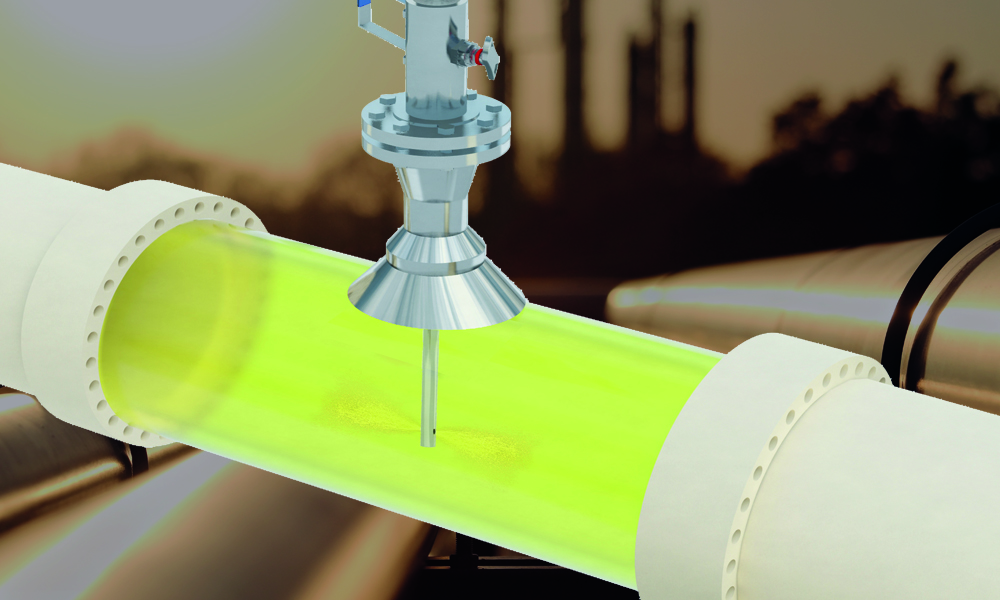

Our customers can use the remote visual inspection to check the valve quality before shipping.