Factory standards in the oil and gas industry - as varied as the countless tapas variations

I have now been in the field for more than 25 years and support my customers exclusively in Germany. I have noticed that the measurement technology in the plants is carried out very differently.

Just as there are endless variants of Tapas, there are also many different types of measurement technology. As a passionate Tapas connoisseur and with over 30 years of professional experience, I know both areas very well.

Not only the measuring system, e.g. how to determine a flow in a process plant, whether by mass, vortex meter, magnetic-inductive, ultrasonic or differential pressure flow measurement is different, no, even in the application differential pressure or pressure there are a variety of possibilities.

Work standard variety in process engineering

Most process plant operators have their own factory standards. Even within a customer group, whether it is a refinery, petrochemical plant, power plant or chemical plant, this factory standard varies greatly including within the same applications.

But how is such a factory standard actually created? Quietly and secretly behind closed doors?

Hmm, that certainly happens now and then. But to create a conclusive and efficient factory standard, the plant operator usually works together with the supplier.

In my blog post, I would like to show you a practical example of how we have successfully standardised a factory standard for pressure measurement working together with a large refinery operator.

Standardisation of pressure measurement

The task was to standardise the pressure measurement. A technical standard already existed at that time. However, this was outdated and much too inefficient.

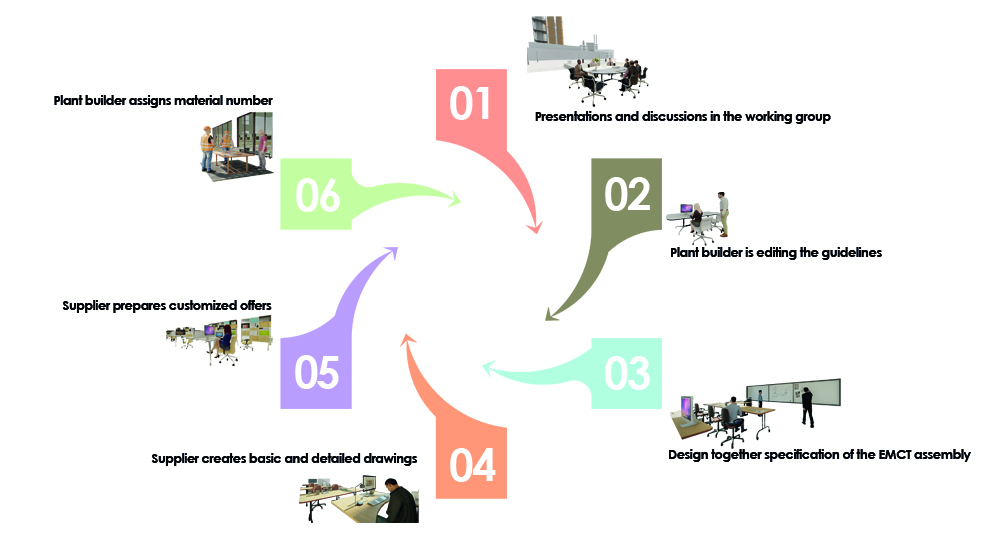

A common method for this is accomplished in several steps. For a better understanding, I have shown them in an information graphic:

- Presentations in the working group (manufacturer)

- Editing the guidelines (customer)

- Specification of the electrical measurement, instrumentation and control technology (EI&C) assembly (customer/manufacture)

- Creation of basic and detailed drawings (manufacturer)

- Preparation of offers (manufacturer)

- Assignment of material number (customer)

Customised application solution

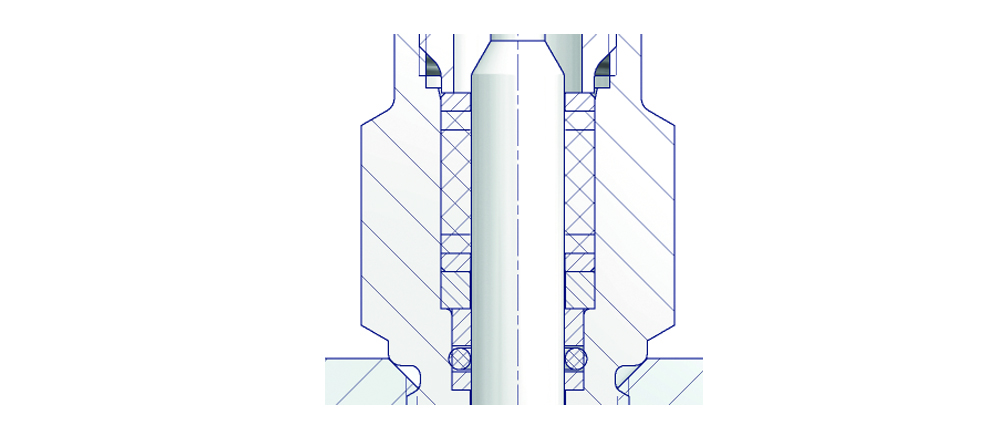

From the intensive discussions, we succeeded in developing a customer-specific, user-friendly solution for the standardisation of pressure measurement. Among other things, this resulted in an instrument monoflange with the “Block & Bleed” function:

Anti-tamper grip

The valve bonnet is equipped with an anti-tamper grip, which prevents unintentional operation. The hidden spindle can only be operated with the help of a supplied socket spanner. Further possibilities for locking using a lock, a seal with wire or a cable tie are also possible.

Leakage test

Approximately 80% of the application cases in a refinery must meet the tightness requirements of the TA-Luft ((German Clean Air Act). In order to avoid confusion and unnecessary variants, we have jointly decided to equip each valve/packing with the TA-Luft option.

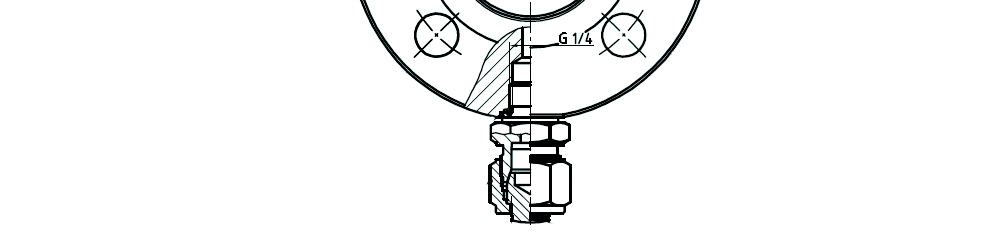

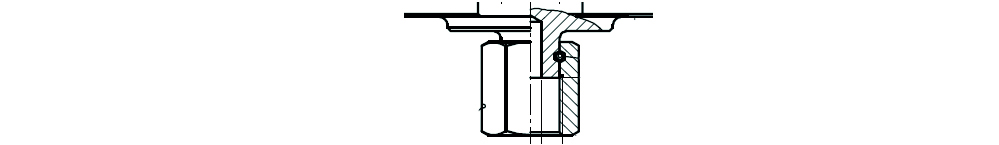

Tapered threads, which seal over their flanks, such as a NPT threads, have been avoided throughout. Instead, parallel threads are equipped with a defined sealing ring. The application with G-thread is familiar to all fitters and has proven itself over many decades. A compression fitting with an integrated plug as a seal enables individual use as a test or vent connection.

Tapered threads, which seal over their flanks, such as a NPT threads, have been avoided throughout. Instead, parallel threads are equipped with a defined sealing ring. The application with G-thread is familiar to all fitters and has proven itself over many decades. A compression fitting with an integrated plug as a seal enables individual use as a test or vent connection.

For this concrete example the new customer standard was frozen about 6 years ago and is meanwhile in the 2nd edition based on learnings in the field and was carried over to addtl. standards. Since then we now have the pleasure to deliver this design to their EI&C applications.

And now back to the Tapas Variations…..

Image Source: © Shahriar_01 (Fiverr) & AS-Schneider