Am I building the plant my client wants? What needs to be done to make it so? As a plant builder, you have probably asked yourself those questions too many times. Even more, you sure know the answers. They imply technical assurance under the project’s budget and schedule constraints.

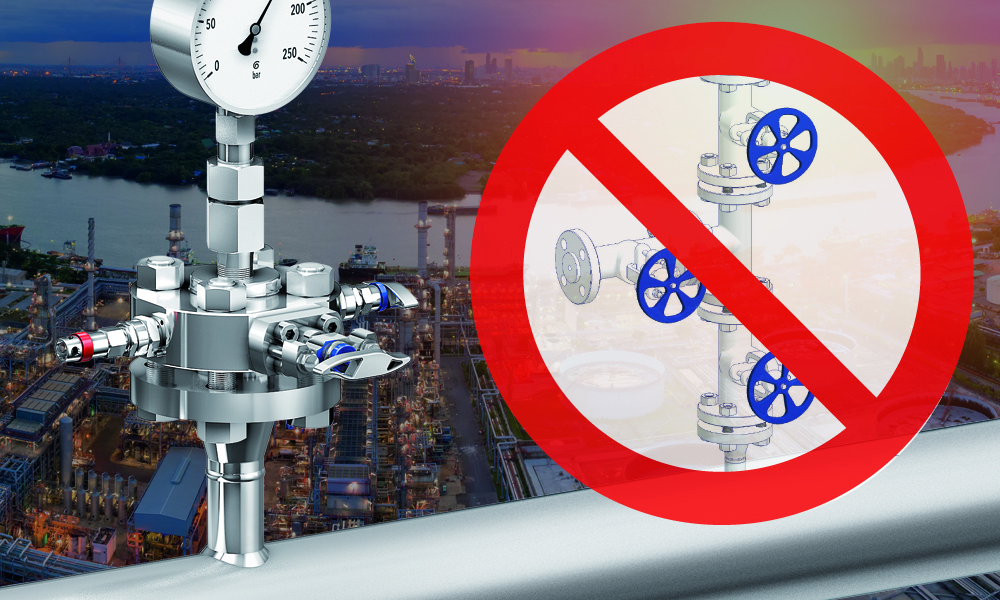

Throughout my career as an instrumentation hardware specialist, I have observed a significant trend among EPC engineers, particularly in the chemical industry. When choosing accessories for a measurement system, they tend to prioritize investment savings over the total cost of ownership (TOC). Even when those savings don’t guarantee smooth upkeep for the facility.

Continue reading