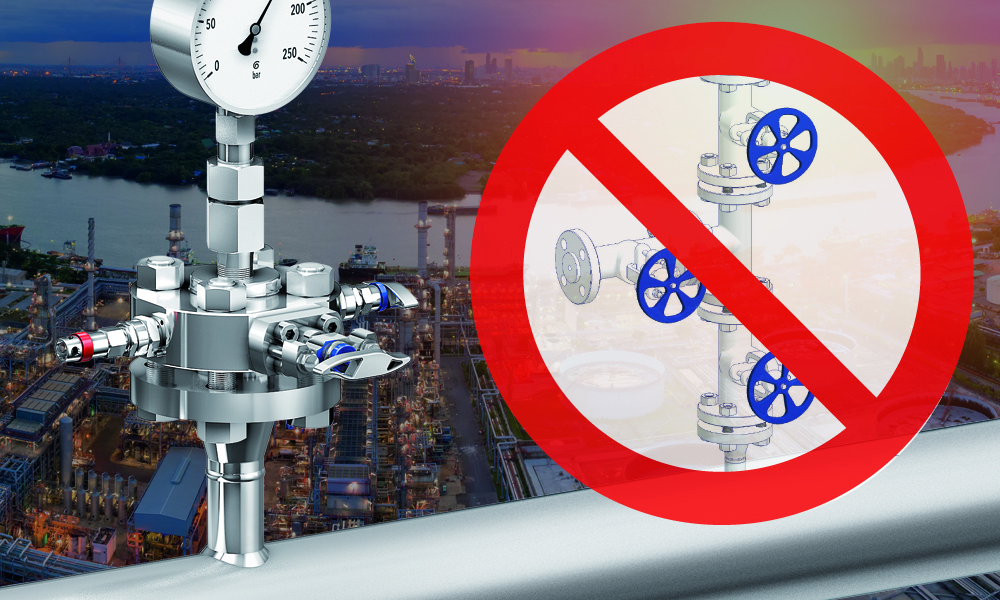

Block and Bleed and Double Block & Bleed isolation systems are used in process instrumentation to isolate your instrument from the main process line. The isolation valve(s) stop the flow from the upstream, while the bleed valve removes any pressure or residual product that remains in the downstream section or in the section between the two valves.

Use of block and bleed valves is mandatory in many industrial processes for isolating the measuring instrument from the process line. This allows maintenance work to be performed on the instrumentation without the need to shut down the entire operation. There are two approaches to the installation of a block and bleed or a double block and bleed setup.

Continue reading