Ultrasonic Flow Meter Applications

Ultrasonic flow meters are used to measure hydrocarbon gases in applications which require wide range (turn-down ratio), very high or low flow, low restriction, high accuracy or any combination of these from low pressure to super-high pressure.

All gas transactions are made under such predetermined/agreed conditions for example Standard Cubic Feet, Normal Cubic Feet where the reference temperature and pressure are normalized and corrected to.

All volumetric flow meters when used for gas, natural gas or steam applications need to be normalized and compensated for pressure and temperature variations as they have a huge impact on the density of the gas and as a consequence on its standard volume. Therefore it is often required to install a pressure measurement so the flow computers can compensate for it.

The pressure hook-ups can be installed in 2 ways

1) Remote Installed Hook-up

Using a remote installed hook-up, which requires manufacturing and installation of tube runs, fittings, additional valves or expensive pipe stands.

2) Close Coupled Manifold

Using a Close Coupled Manifold which reduces potential leak points and provides a safe compact leak free measurement installation.

The expectation of the users is to get an accurate result of the pressure measurement. But long gauge lines will definitely cause inaccurate measurements because the lines dampen the signal read at the pressure transmitter. Liquids and condensate in long gauge lines can potentially freeze causing measurement error.

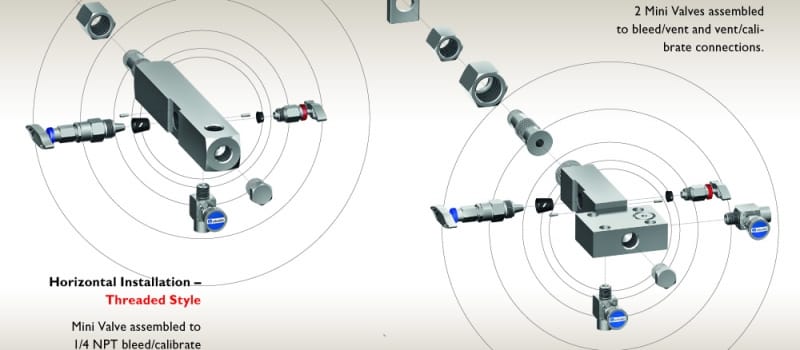

Close Coupled Hook-ups – Horizontal Installation

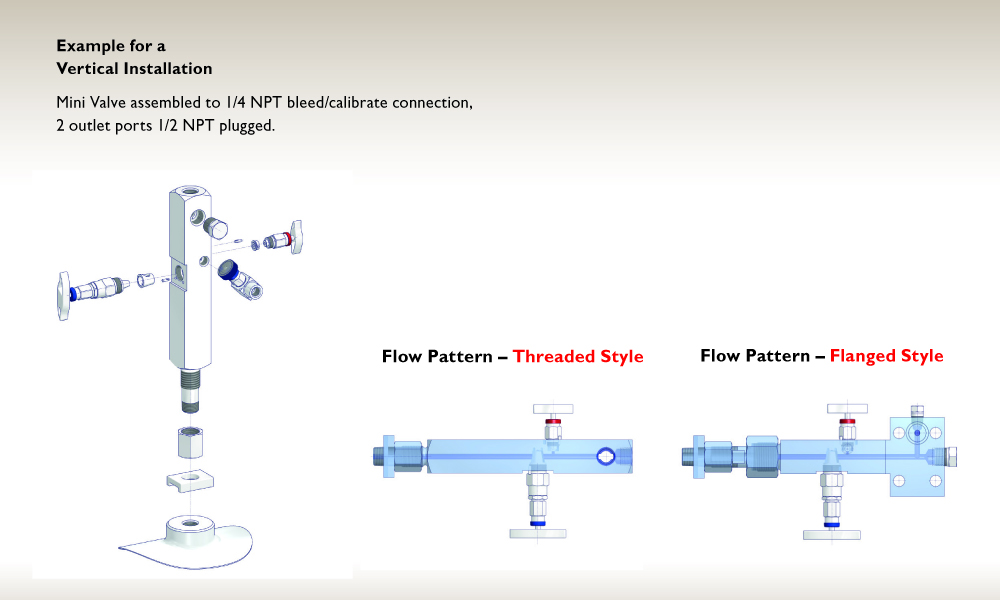

Close Coupled Hook-ups – Vertical Installation

Features and Benefits of a Close Coupled Hook-up

- Minimizes or Eliminats of Gauge Line Errors

- Reduces Freezing Issues

- Reduces Installation Cost – no need to manufacture and install tube runs, fittings, and expensive pipe stands

- Reduces Potential Leak Points associated with NPT Connections

- Provides a Safe Compact Leak Free Measurement Installation

Image Source: © AS-Schneider