Every engineer encounters the challenge of having to choose one technology over another. A notable example is specifying the valve solution for a given process line. Sometimes the choice is evident. Other times, it is a tight horse race of options. In light of that, in this article, I want to focus on a topic I frequently get asked about: the differences between floating and trunnion-mounted ball valves. Selecting the most valve of the two for a specific service could be tricky at times. Thus, knowing what sets them apart helps a long way. Read on to learn about both valve solutions. My goal is to lead you to identify which design is more appropriate.

Continue readingWhat is a valve manifold and where are valve manifolds used?

Valve manifolds are flow management devices of ever-growing interest for operators, maintainers, and design teams worldwide. Even under today’s landscape of ongoing innovations, they continue to be a go-to technical solution for fluid control in systems. When two or more valves are involved, that is.

Since their deployment extends across diverse processes in several industries, it is only fitting to seize the opportunity to offer knowledge on them.

What are valve manifolds? When to use them? What configurations are available?

These are some of the questions to address in this introduction feature. Please, continue reading below to get the details.

Continue readingTypes of valves used in piping and how to classify them

This article presents an overview of valves, their functions and the commonly used types of valves in the industry. The design principle, application areas, benefits and disadvantages of various types of valves are presented. Different methods of valve classification are also discussed to highlight the key considerations in valve selection.

Continue readingHow to isolate a process line from process instrument with a DBB valve

Block and Bleed and Double Block & Bleed isolation systems are used in process instrumentation to isolate your instrument from the main process line. The isolation valve(s) stop the flow from the upstream, while the bleed valve removes any pressure or residual product that remains in the downstream section or in the section between the two valves.

Use of block and bleed valves is mandatory in many industrial processes for isolating the measuring instrument from the process line. This allows maintenance work to be performed on the instrumentation without the need to shut down the entire operation. There are two approaches to the installation of a block and bleed or a double block and bleed setup.

Continue readingReliable and accurate sampling system for natural gas applications

My previous article in this series explained what are the main issues in obtaining a representative sample in NG applications.

This case study demonstrates a reliable sampling solution currently used by plant operators. It helps plant operators to obtain representative samples.

Continue readingWhat are the main issues in obtaining a representative sample in NG applications?

In this article, I present the major issues associated with obtaining a representative sample in NG applications. The article explains what is representative sampling, and why sampling is important in the natural gas industry. I discuss factors that determine what should be a suitable sampling frequency in a process, and which sampling standards can be followed to ensure representative sampling.

Several major issues in obtaining a representative sample, and common design flaws that lead to poor sampling are presented and discussed. In addition, I present how a suitable probe length can be determined and how the probe should be installed. The different types of commonly used sampling probes are also compared and discussed.

Continue readingHow to avoid hydrate formation during underground natural gas storage in salt caverns

In this case study, I focus on how to avoid hydrate formation in natural gas pressure measurement pipelines. I describe the traditional approach to avoid hydrate formation during natural gas storage in salt caverns. Furthermore, I explain a patented customer solution that AS-Schneider has industrialized.

Continue readingUnderground natural gas storage in salt caverns and the challenge of hydrate formation

Many of my customers use natural gas storage facilities in order to balance out low and peak demands over the course of a year.

Over the years, I have gained a lot of valuable experience on this topic. This knowledge is what I would like to share with you in the context of a blog article.

4 most important mechanical isolation methods of process piping & equipment

Positive isolation is the isolation of process piping, equipment, or vessels from hazardous materials such that it is impossible for the material to enter the work area. Positive isolation must remove all risk of accidental reconnection to the source of the hazard due to equipment failure or operator error. There are several methods of achieving positive isolation some of which are discussed below.

Continue readingCase Study: High temperature DBB valves for steam injection – A common enhanced oil recovery method

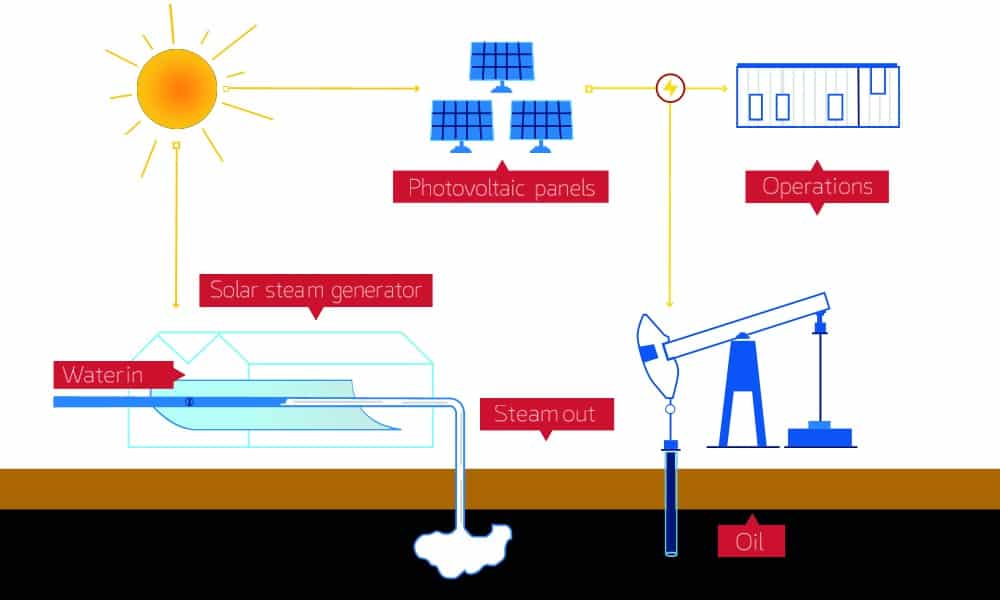

Case study about high temperature Double Block & Bleed valves for steam injection. We have successfully installed the DBB valves at the Amal oilfield in Oman which uses “green” steam, generated at the Miraah solar thermal facility.

Continue reading