4 most important mechanical isolation methods of process piping & equipment

Positive isolation of process piping, equipment, or vessels

Positive isolation is the isolation of process piping, equipment, or vessels from hazardous materials such that it is impossible for the material to enter the work area. Positive isolation must remove all risk of accidental reconnection to the source of the hazard due to equipment failure or operator error. There are several methods of achieving positive isolation some of which are discussed below.

4 most important mechanical isolation methods

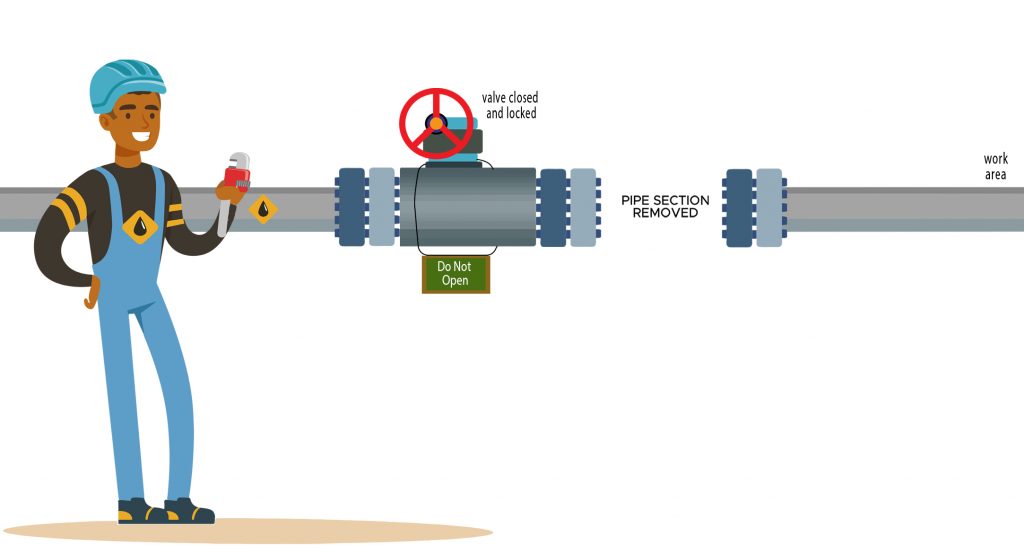

Spool removal or air gapping isolation

Spool removal or air gapping is a line-breaking method that involves removing a spool section from the piping and installing a blind flange to block the flow from the source. This method is highly reliable and secure as it achieves actual, physical separation of the source from the equipment. The downside of this method is that if the pipeline has a large nominal size, the spool can be very bulky to disconnect, remove, and replace after the maintenance work. Lifting equipment and additional manpower are required to achieve isolation. Furthermore, maintenance workers may have to deal with rusted bolts and misaligned gaskets extending the downtime as flange surfaces are cleaned and a new gasket is inserted. This isolation method is very time-consuming and is not suitable for routine maintenance work and emergency situations.

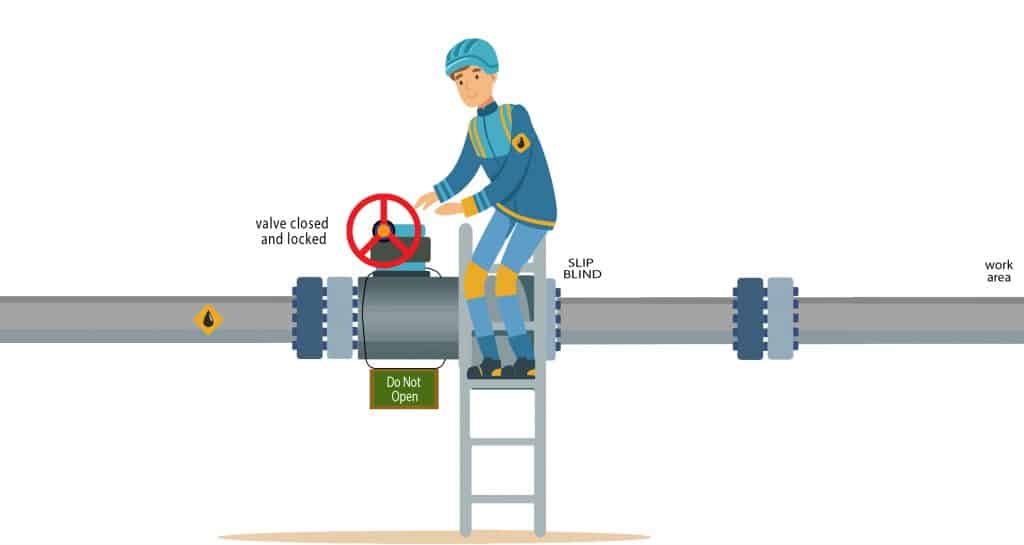

Blind isolation

Blind isolation refers to the insertion of a blind (spade) between two flanges. In installations where spool removal is difficult to implement, isolation by a valve and line-rated spade provides the next highest level of security. The blind may be inserted by replacing a spacer ring with a line blind or rotating the blind end of a spectacle blind into place that has been installed on the flange. A spectacle blind is a permanent installation designed to simplify the change-over between a blind and an open-spacer. Blind isolation still requires physical labor and manual intervention consuming manpower, resources and time, especially with large bore piping systems. Maintenance workers may still encounter problems like rusted bolts or a damaged gasket that must be replaced. The blind portion of a spectacle blind often gets corroded and may need to be scraped and cleaned before it can be used. Spool removal and blind isolation are generally recommended for situations where isolation is expected to last longer than a month.

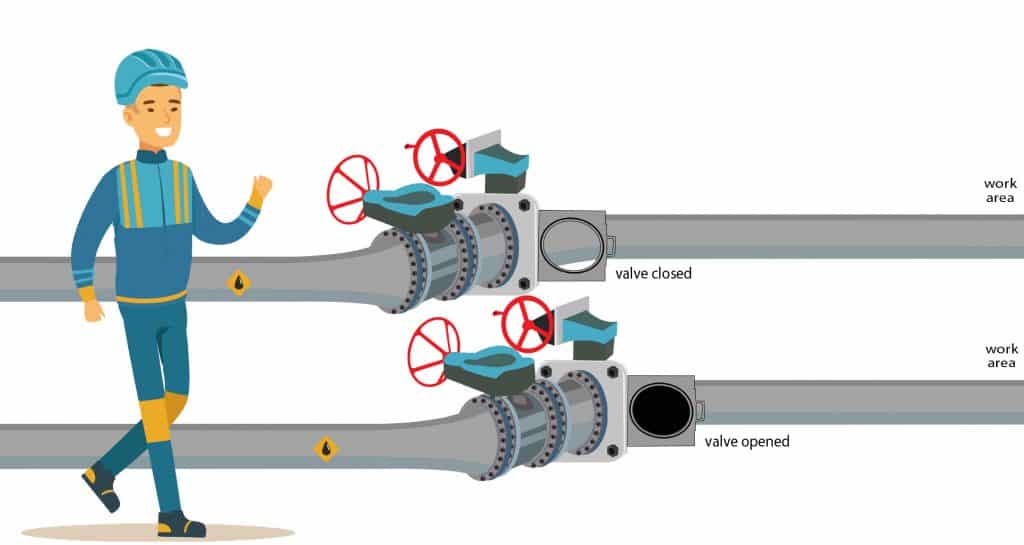

Single valve isolation

As the name suggests, single valve isolation uses only one valve to isolate the source from the work area. The isolation is critically dependent upon the reliability of the seal and the integrity of the single valve operating stem. Such a system may only be used for the purpose of swinging a spectacle blind, inserting a line spade or fitting a blind flange to achieve higher integrity isolation. Single valve isolations may only be considered for routine, short duration, low pressure, cold work.

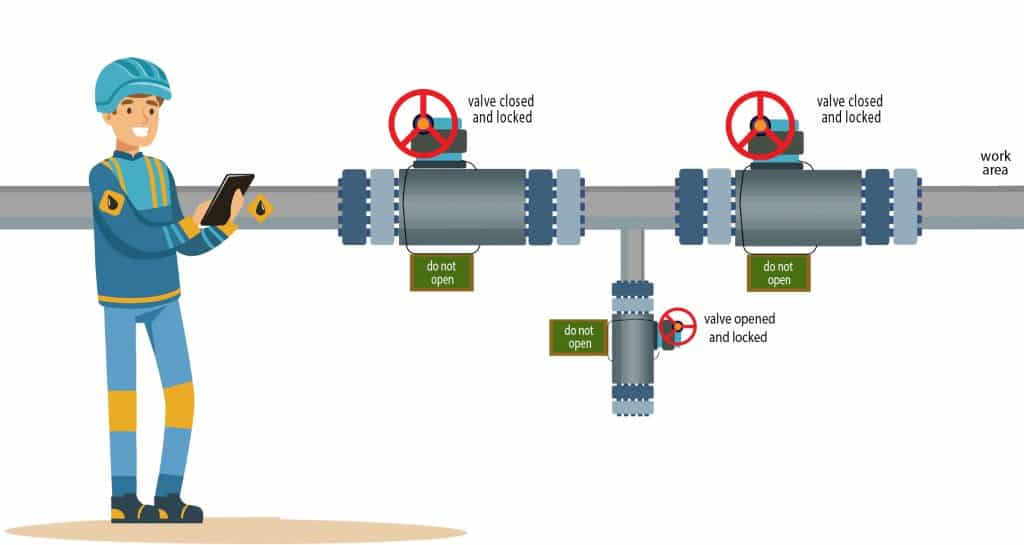

Double block & bleed isolation

A Double block and bleed (DBB) isolation system is considered to be the most secure form of valve isolation. It consists of two valves in series, with a bleed valve in between, that allows the pressure/material, between the two valves, to be bled through a vent directed to a safe location. To achieve isolation, the two main valves are closed and the bleed valve is opened. The DBB configuration shuts down a section of the pipe on both sides rather than just one. Double block and bleed isolation reduces the risk of harm to people and the environment. It is considered to be the minimum sole means of isolation for cold routine short duration work at moderate to high pressures.

Complex work processes, combined with tight maintenance windows, present a challenge for installation and maintenance personnel in the oil & gas sector and other industries. Many companies have adopted the policy of mandatory DBB isolation when maintenance work is being performed on field equipment. A DBB installation can reduce the maintenance and installation effort considerably while providing a process safety solution for positive isolation on both sides. In addition to simplifying maintenance, DBB systems are also useful in:

- Preventing product contamination

- Removing installed equipment for service

- Controlling transmission and storage

- Chemical injection and sampling

- Meter calibration

- Isolation of instruments such as pressure indicators

Types of double block and bleed installations

There are two main approaches to achieving a double block and bleed configuration. In the conventional approach, standard valves and spools are used to form a DBB setup. The modern approach to implementing DBB isolation is to use a specially designed, compact, single unit that incorporates the same functionality.

Conventional installation

The traditional technique, employed by pipeline engineers to generate a double block and bleed configuration, is to use three valves; two for isolation and one to bleed the section between the two valves. Typically, two suitable valves are connected to a spool piece. The bleed valve is retrofitted in the center spool to form a DBB arrangement.

In the oil and gas industry, most double block and bleed valve systems are still conventional installations. The conventional DBB installation is a time-consuming process that can prolong and complicate the periodic maintenance work and daily operation.

Compact DBB valves

A compact DBB valve installation consists of two block valves and a bleed valve in a single unit or manifold. The integrated unit replaces the three valves and spool contraption used in conventional installations. A compact DBB valve provides the same double block and bleed functionality in a single unit as the conventional installation. It can isolate piping on both sides of the valve while allowing venting/bleeding of the cavity between the seats through the bleed valve.

Advantages of compact DBB valves

In the oil and gas industry, the use of compact DBB valves for pressure isolation is progressively becoming more popular, however, they have still not been universally adopted. While in some instances a compact DBB valve, suitable for the specific process requirements, may not be available, in many cases engineers have the choice of opting for a compact DBB unit. Choosing a compact DBB valve over conventional installation offers several advantages. Some of these advantages are discussed below.

✓ Reduced weight

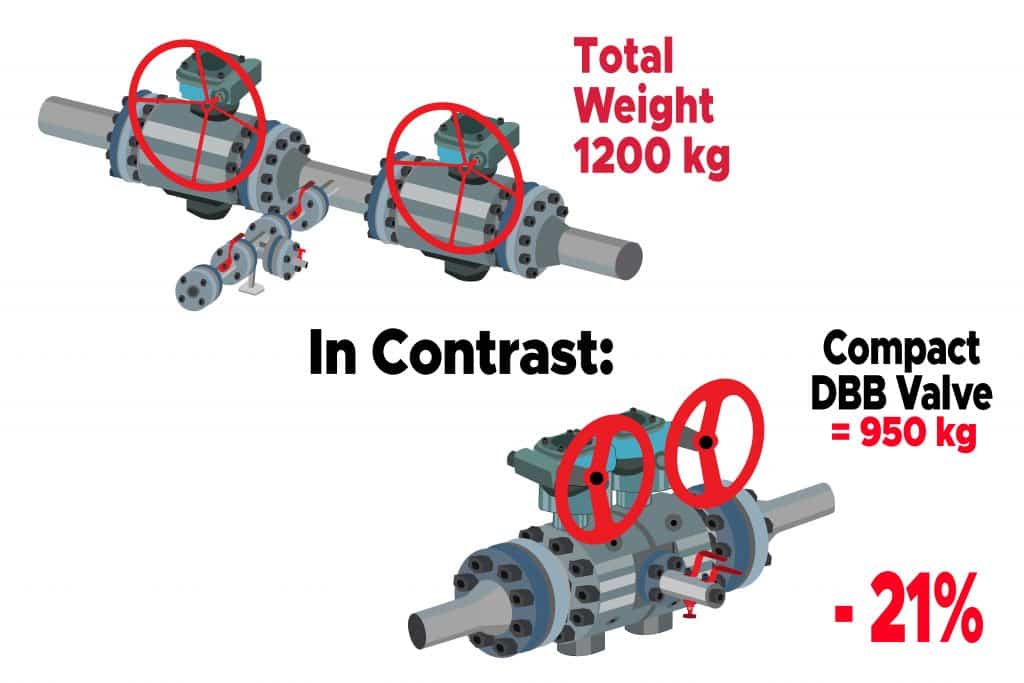

A common conventional DBB installation, in the oil and gas sector, consists of two 6″ 1,500 class ball valves with connecting, spools, gaskets, flanges, nuts and bolts. The complex installation process requires as many as 41 steps and the resulting configuration can be very bulky, weighing as much as 1200 kg. A compact DBB valve that serves the same purpose weighs only 950 kg. If a facility has 10 different DBB installations, using compact DBB valves instead of conventional installations can eliminate over 2.5 tons of weight.

✓ Compact assembly

Compact DBB valves have a small footprint that leads to space savings. They can be installed in tight spaces where conventional DBB installations may not fit. Since all the valve components are housed in an integrated single unit, the space required for the installation is dramatically reduced. A conventional installation not only takes up more space but is also more laborious to install as it requires connecting, securing and testing all the individual components.

✓ Simplified maintenance and handling

Compact DBB valves offer significant advantages for maintenance personnel. The integrated valves can be serviced faster as compared to conventional installations and minimize downtime. The lighter and less bulky, DBB compact valves are easier to handle and require less effort to move the valve to or from the installation point. Conventional DBB assemblies require a greater effort to dismantle and refit during maintenance and hence necessitate the use of additional personnel and work hours.

✓ Reduced leak paths

Leaks can contaminate the product, create a safety or environmental hazard, or increase the risk of fire. The probability of an accidental leak increases with the number of joints in the piping system. A conventional DBB installation has significantly more potential leak paths as compared to a compact valve. The integrated compact DBB valve design eliminates the need for several joints that could potentially leak over time or require periodic maintenance. The use of compact DBB valves can, therefore, help in increasing process reliability.

✓ Reduced cost

Thin margins and increasing competition in several major industries is forcing manufacturers to reduce production costs without sacrificing the safety and reliability of the process. Choosing compact DBB valves to replace conventional installations not only reduces the overall project cost but also cuts maintenance expenses. If the individual valve testing, transportation and installation costs are factored in, the resulting savings from the use of compact DBB valves become even more attractive. Furthermore, the reduction in shut downtime increases productivity, thereby boosting revenue and minimizing per unit cost.

✓ Operational advantages

Compact DBB valves also offer several operational advantages. The isolation valves are full bore and allow unhindered flow through the orifice with a negligible pressure drop across the unit. These full-bore valves also allow the pipelines to be pigged without any problems. The compact DBB unit has a smaller cavity between the isolation valves that requires a shorter drain time. In addition, some compact DBB units can be operated with a single actuator, instead of two, for faster operation.

✓ Highest safety

Safety regulations such as Occupational Health and Safety (OHSA) and engineering codes/practices provide guidelines on the need for different kinds of isolation and isolation levels. The requirements can vary depending on the industry standards, country-specific legislation or company policy. Compact DBB valves that meet the requirements of OSHA to provide a safe solution for positive isolation on both sides are available on the market. Conventional installations, on the other hand, must be internally tested and verified to meet these requirements in order to reduce risk exposure.

The use of a DBB valve provides a high level of isolation that is second only to actual physical separation. A compact dual ball DBB unit can create a quick barrier by a quarter turn which is a time-saving option in emergency situations. Even when a gearbox is used, in larger bore size units, only a few turns of the handwheel are sufficient to achieve isolation. Compact DBB units normally also have locking facility to comply with lock-out/tag-out procedures specified in safety protocols.

Conclusion regarding mechanical isolation methods

During a maintenance shutdown, effective piping isolation is essential. A double block and bleed isolation system is considered to be the most secure form of valve isolation. A DBB system can be implemented using the conventional method with separate valves connected via spools in a DBB configuration. The modern approach, however, is to use a specially designed compact DBB valve. A compact DBB valve offers the benefits of reduced weight, space saving, easier maintenance and handling, reduced risk of leaks, lower cost and higher safety, in addition to other operational advantages.

Image Source: © Pongpob (Adobe Stock) & Matrivgraphics (Fivver) & AS-Schneider