The chemical industry uses flush rings for diaphragm seals. These rings prevent clogging of the instrument connection. The technician mounts the ring between the process flange and the diaphragm seal. It has flushing ports and membranes. The flushing ports allow users to wash out particles from in front of the membrane. It also has a pressure chamber, which users can vent, drain, or fill with cleaning liquid. The user can then flush the chamber.

Continue readingProvide usability for EPCs

In plant construction, you often come up against challenges where standard valves no longer fit. Then, you need professional support who can advice you what to do when standard solutions don`t meet the requirements of the installation.

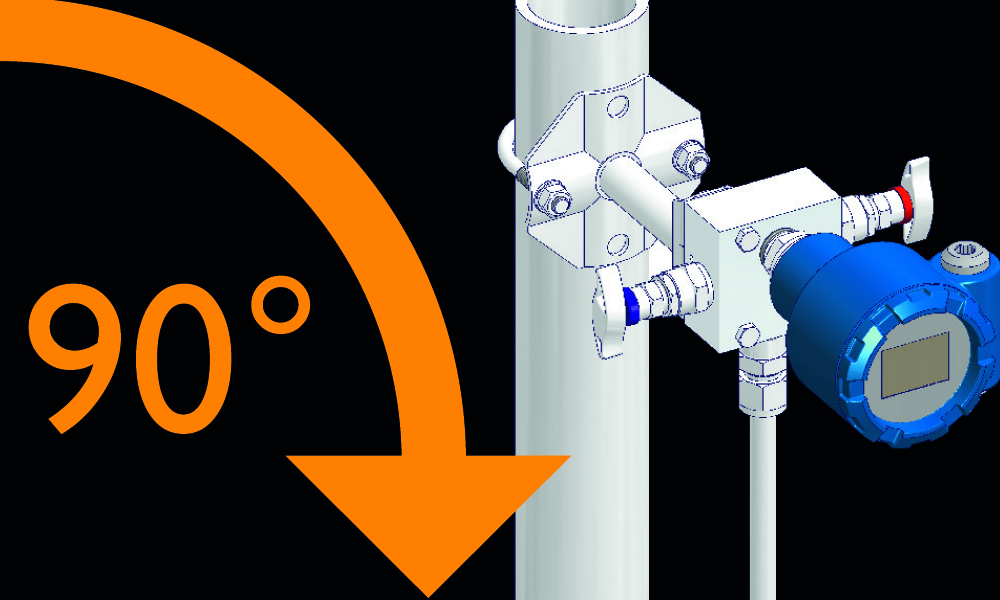

Some time ago we have created a simple but very helpful solution for a pressure gauge manufacturer. The solution refers to the alignment of the pressure gauge display.

Continue readingValves in extreme cold: 3 criteria are decisive

Whether in Alaska, Norway or Russia: Industrial valves, such as those used in chemical plants or the oil industry, are exposed to extreme cold as low as -55°C in some regions. However, not all industrial valves are suitable for operation in extreme cold. Three criteria are decisive.

Continue readingUltrasonic Flow Meter Applications

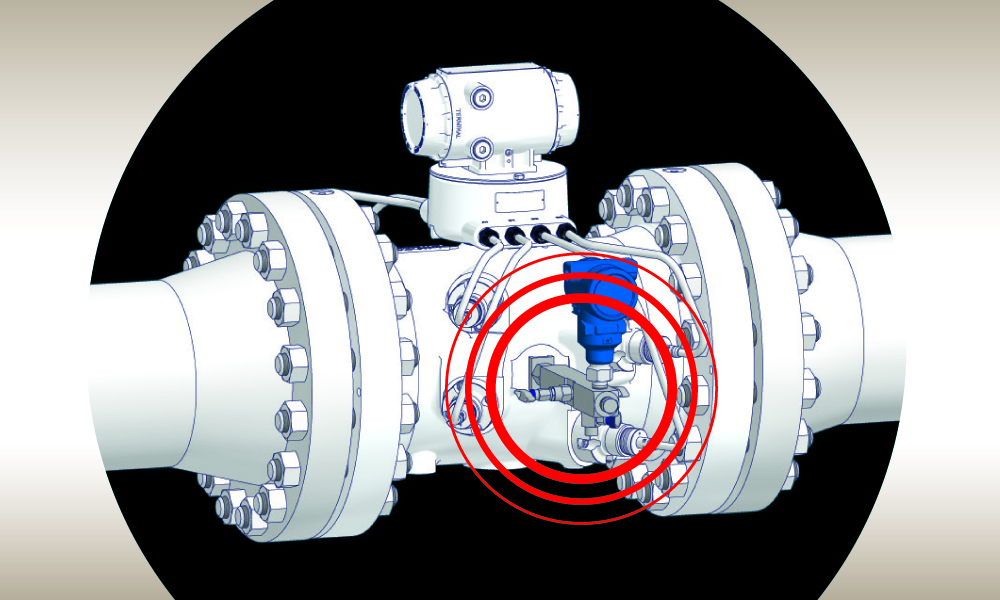

Ultrasonic flow meters are used to measure hydrocarbon gases in applications which require wide range (turn-down ratio), very high or low flow, low restriction, high accuracy or any combination of these from low pressure to super-high pressure.

Continue readingUser report – Close Coupled Installation Concepts

The Indian Oil Corporation Ltd. could reduce the installation effort from 16 hours to one hour by using Close Coupled Installations.

Continue readingDoes the seal ring fit? Avoid bad surprises.

Direct mount manifolds for direct mounting on pressure and differential pressure transmitters are normally protected against overheating by hot process media by means of correspondingly long impulse pipings. Nevertheless, many users demand that the manifolds and their flange connection to the transmitter can easily withstand even higher temperatures. For this, the manifolds must be equipped with gaskets made of graphite. This means they can easily be used at up to 550 degrees Celsius – much more than required by the current EN 61518 / IEC 61518 standards.

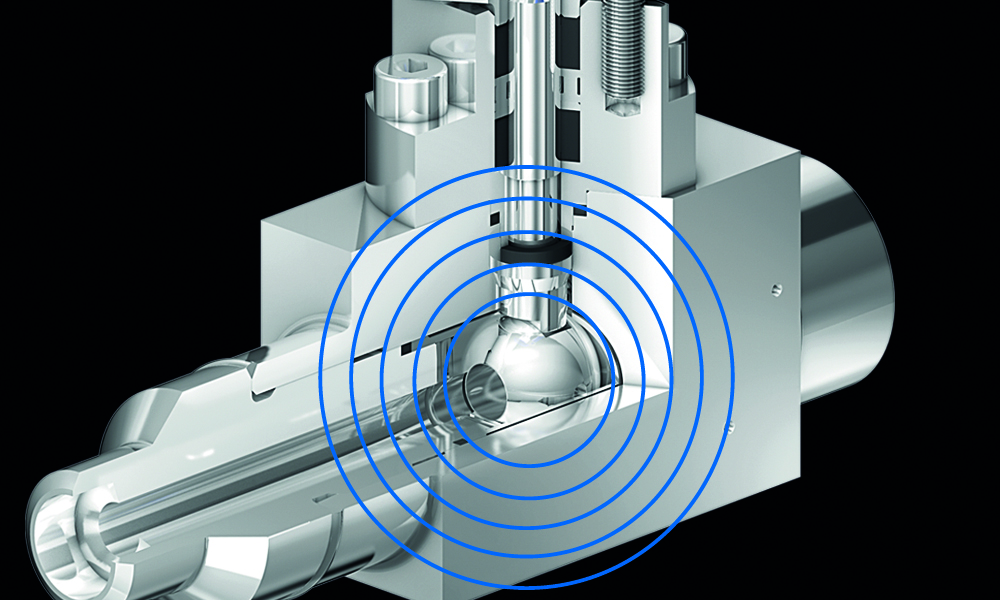

Continue readingMetal seated ball valves for extreme operation conditions

Our customers are often faced with the challenge of determining exactly the right valve/manifold application for extreme operating conditions. For process plants I can recommend the use of metal seated ball valves if abrasive products, high temperatures and pressures are present. Extreme operating conditions with temperatures up to 450 °C and pressures up to 420 bar require a special sealing technology for ball valves. Standard soft seated ball valves simply aren’t ready for this kind of requirements. Their plastic seats would fail.

Continue readingSmall, but powerful: Low torque for a smooth operation

During my last 12 years in the instrumentation business I have been asked many times at which pressure a manifold can still be operated. As well as, what is the difference between the following two non-rotating stem designs:

Continue readingTamper-proof solutions

Pressures of several hundred bar, temperatures up to 600 degrees Celsius: Industrial valves, such as those used in power plants, the oil and gas industry or in chemical process systems, work under the most arduous conditions. In such cases, safety is the most important aspect. Not only the enormous pressure, but also the often toxic or aggressive process media can quickly become a hazard for people and the environment.

Continue reading