We are all facing many restrictions due to the pandemic. Therefore, we need to find ways to still provide the best possible support to our customers. One digital service that our customers can use is our third party inspections – better said remote inspections.

Our customers can use the remote visual inspection to check the valve quality before shipping.

Resistant and safe bellow-sealed needle valves for a national space agency

This blog salutes all the space agencies working for space research & technology. AS-Schneider joins you at the cutting edge because we support the aerospace industry leaders and supply specific bellow-sealed needle valves for their space projects.

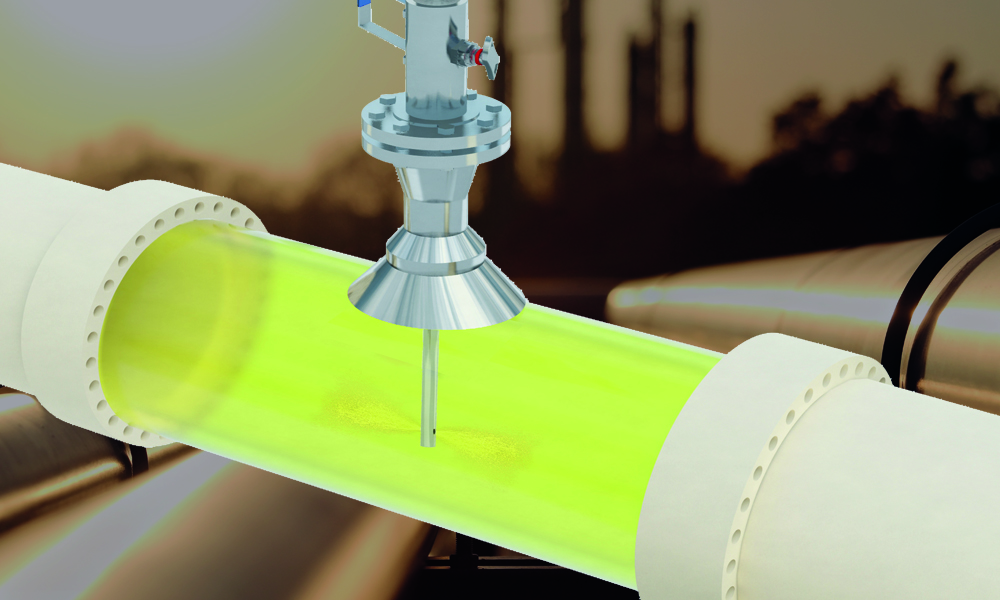

Continue readingUnderstanding Injection/Sampling DBB Valves with Probe & Support Collar Application

Based on the blog post “Chemical Injection Quill for Oil & Gas” written by my colleague Kevin Alamag, I would like to dive more into the depth of the application fields of Injection / Sampling DBB Valves. In my course of work talking to OEMs, EPCs, end-users and other clients on this injection/sampling area, I was surprised to know that there are many misunderstandings on this small but important product range within the whole process.

Continue readingHigh pressure valves up to 15,000 psi in offshore application

We all know, pressure is one of the most important process parameters, in the field of measurement and control. Pressure measurement under extreme applications are done for enormously high-pressure range. These measurements must be safe and precise, for which we need reliable valves to maintain tight control and regulation at these high pressures.

Continue readingChemical injection quill for oil & gas application

To support users in their proper planning and technical evaluation, I would like to share some information about one less-familiar product in the industry, the chemical injection quill.

Continue readingChloride induced stress corrosion cracking (CISCC) in pipelines

The energy sector has passed through various atmospheric and process environmental challenges. How big is the challenge? It depends on the region, application, process media, and industry. It is also not limited to these factors. One of these challenges is Chloride Induced Stress Corrosion Cracking (CISCC).

Continue readingDBB system in instrument piping – a cost effective safety solution

I remember very well when we started the development of our Double Block & Bleed Valve Series. We called it “VariAS-Blocks”. Production started 20 years ago, and we have made many improvements since there.

We based the design on the standard SHELL MESC SPE 77/165 (which the MESC SPE 77/170 superseded) and EEMUA 182.

Continue readingWhy do material traceability and type 3.2 certification matter?

Today, manufacturing has become global. Imagine a salesman in Europe or America. He supplies his product for a project in the Middle East, coming from their factory in India, which sources its raw material from China or other parts of the world. It has support and customer service from Southeast Asia. This scenario is common in companies with operations across the globe.

Continue readingEmergency aid for leaking valves and manifolds

Severe problems can arise if industrial valves are defective in chemical plants or in oil or gas applications – possibly with leaks. The broken industrial valves must be replaced as soon as possible. Without long delivery times.

Continue readingCryogenic valves for LNG application – Part 2

In our second part of the cryogenic valve series I would like to responsive on questions like “What are the challenges of using cryogenic?”, “Selecting a valve for cryogenic service.”, “How can engineers ensure tightness of cryogenic valves?” and “What should engineers pay attention to during assembly of cryogenic valves?”.

Continue reading