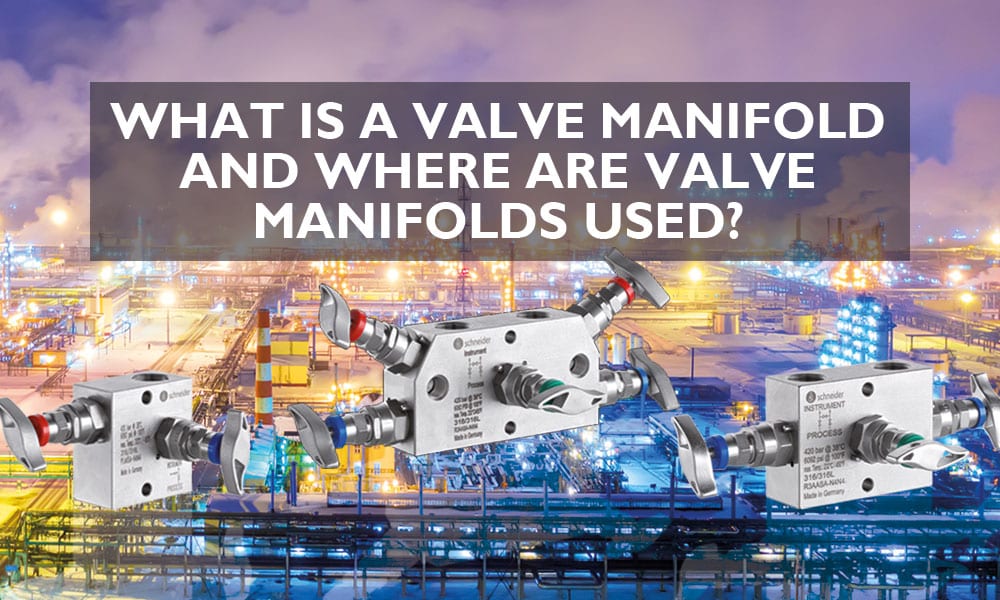

Valve manifolds are flow management devices of ever-growing interest for operators, maintainers, and design teams worldwide. Even under today’s landscape of ongoing innovations, they continue to be a go-to technical solution for fluid control in systems. When two or more valves are involved, that is.

Since their deployment extends across diverse processes in several industries, it is only fitting to seize the opportunity to offer knowledge on them.

What are valve manifolds? When to use them? What configurations are available?

These are some of the questions to address in this introduction feature. Please, continue reading below to get the details.

Continue reading