Building a new facility or upgrading an existing one is a high-stakes mission. Even with modern technological and mechanical advances, there are thousands of tasks to juggle. Each is imperative for the delivery of an asset that withstands the site conditions and the challenges of daily operations.

Continue readingPractical test installation of a DBB Piping Ball Valve at a gas storage facility

One of the things that I enjoy the most about my job is discussing new improvement opportunities with clients. Situations like that push me to engineer viable solutions that solve operational setbacks, so they can enjoy more reliability and safety at work. And that was what happened when I designed the practical test installation procedure I’m about to share. It was for a double block and bleed (DBB) ball valve installed in a gas storage facility.

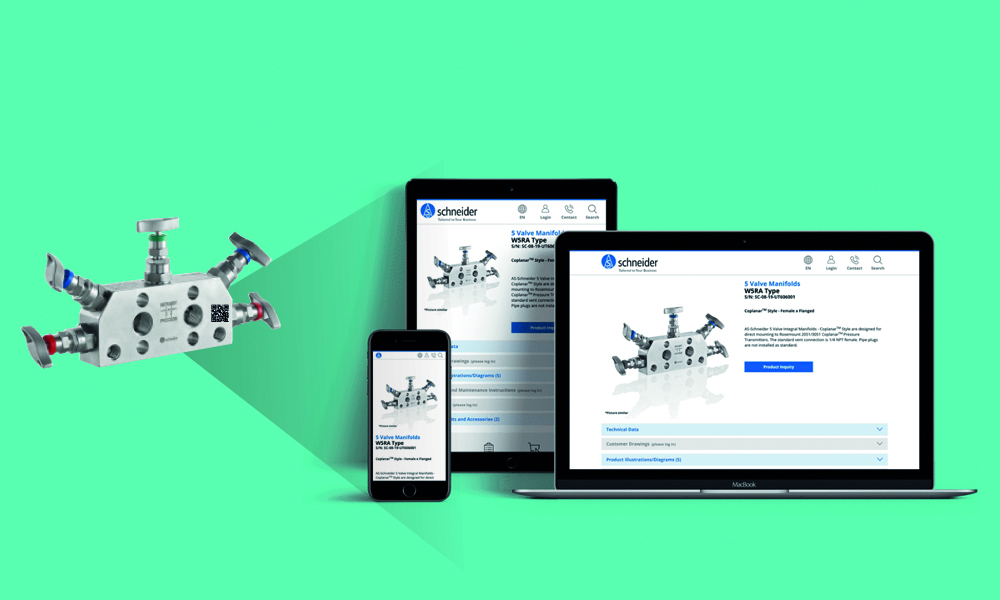

Continue readingStatic digital twin functionality for valves and manifolds

The Industrial Internet of Things (IIoT) is getting more and more traction. The IIOT promises to transform processes of the industry. It demands the securing and availability of far higher amounts of data, at far greater speeds. Often the data is moved into cloud for big data processing. Connectivity and scalability are mandatory.

Continue readingEmergency aid for leaking valves and manifolds

Severe problems can arise if industrial valves are defective in chemical plants or in oil or gas applications – possibly with leaks. The broken industrial valves must be replaced as soon as possible. Without long delivery times.

Continue readingCryogenic valves for LNG application – Part 2

In our second part of the cryogenic valve series I would like to responsive on questions like “What are the challenges of using cryogenic?”, “Selecting a valve for cryogenic service.”, “How can engineers ensure tightness of cryogenic valves?” and “What should engineers pay attention to during assembly of cryogenic valves?”.

Continue readingUser report – Close Coupled Installation Concepts

The Indian Oil Corporation Ltd. could reduce the installation effort from 16 hours to one hour by using Close Coupled Installations.

Continue reading