Challenges of blending hydrogen into natural gas

We are about to enter a new industrial age. The age of blended gaseous fuels! Blended fuels generate when mixing hydrogen with natural gas in the existing grid. Above everything, blending is an urgent trend seeking to speed up the current decarbonization plans to stop climate change.

There is a key issue about it, though. Hydrogen has different chemical properties than natural gas. Thus, in a blended scenario, the fuel is likely to operate outside the already standardized values. Such a notice calls for special considerations, as the natural gas regulatory framework loses its stamp as a valid reference.

There’s another major factor to add. The technical instructions on hydrogen with focus on valves don’t have approval yet. Systematically speaking, blending is a wide-open scenario.

To bring context to today’s status, we have gone on a detailed research and compiled relevant information from different external sources that comes in handy to prepare for the blending future now. You can read all about it right below.

Legal limits for hydrogen

At this stage, knowing the H2 legal limit for a potential application is first on the list. These are the main findings after overviewing H2 conditions for top activities:

| Application area | Legal limits for hydrogen | |

|---|---|---|

| Hydrogen transportation |

For a biogas source (e.g. power-to-gas), hydrogen transport conditions can be in the form of a gaseous energy carrier via the natural gas grid. The German Technical and Scientific Association for Gas and Water (DVGW) specifies the parameters in worksheets G 260 and G 262.

Hydrogen from electrolysis and synthetic methane must comply with a legal limit of 1%-10% (vol) in the natural gas grid. |

|

| Natural gas vehicles |

DVGW regulations (worksheet G 262) allow injections into the public grid below 10% (vol). Further details you will find in the section "20% hydrogen blending".

DIN 51624 sets a limit value for hydrogen in the tanks of natural gas vehicles specified at 2% (vol). |

|

| Gas turbine | Manufacturers set a 1%-5% hydrogen limit (vol) to avoid machine issues caused by a low-pollution premix in burners "sensitive" to the component. | |

| Underground Pore Storage Facilities | A presence of 1% hydrogen blending is accepted in any gas storage facility. Beyond that, hydrogen's biogas content should not exceed 5% (vol) in underground pore storage areas. This limit avoids the growth of undesirable sulfate-reducing bacteria harmful to the site. | |

A careful and precise balance of the H2 injection quotas into the natural grid is at play to ensure these specifications stay in range and not affect clients or downstream operations.

20% hydrogen blending

The perspectives for blending hydrogen into the natural gas grid aim for escalated growth. This notion pairs well with the plans to produce more hydrogen content gradually.

The current base in the regulations allows 10% (vol) H2 presence in the network as already mentioned above at the point “Legal limits for hydrogen”. Future targets seek to move up to 20% (vol) and an eventual 50% (vol). The ultimate goal is also to have 100% (vol) of H2 in grid sections where is possible. Of course, many actors must work together and align to make it happen. That means mostly the producers, operators, consumers, and government. They are the central figures with the power to push the plans forward.

In the meantime, let’s go over an exciting project seeking to meet the blending of 20% hydrogen in natural gas pipelines.

We are talking about the innovative research project by Avacon Netz and DVGW. A pilot to model hydrogen injection into the gas distribution network to assess the effect on household appliances. Early lab tests are encouraging! They showed that the appliances operated just fine at levels up to 30% hydrogen admixture. The later approval process is subject to tests with a gas containing 23% hydrogen.

H2 tolerance of different components in the natural gas infrastructure

Learning about H2’s tolerance to different components in the natural gas infrastructure is just as poignant as knowing about the legal limits of H2 blending in the existing natural gas grid. To tackle the topic, it was important to look for identifiable patterns in H2’s response to several installations, such as:

- natural gas tanks,

- pipelines,

- gas turbines,

- compressors,

- underground storage facilities,

- ultrasonic, turbine, and bellows gas meters,

- gas pressure regulators,

- valves, and

- properties such as transport capacity and permeation.

During research, a 2013 study led by Müller-Syring et al. for the DVGW came up. Their work centered on the “development of modular concepts for the generation, storage, and injection of hydrogen and methane into the natural gas grid.”

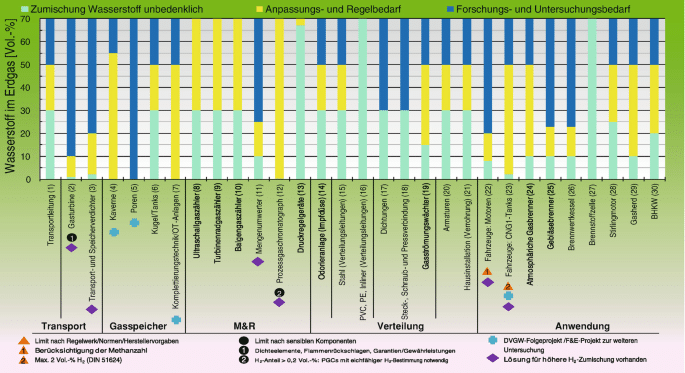

Through this study, it became possible to summarize the relevant data to assess H2 tolerance vs. different components in the natural gas infrastructure. The figure below captures the core findings by depicting essential elements. Feel free to look at it to explore the compatibility evaluation. The basis covers existing data and H2 concentration ranges of 0 to 70% (vol).

Overview matrix: H2 tolerance of selected elements in the natural gas network. (source)

The authors of the 2013 study suggest that the suitability of individual elements of the supply chain for higher hydrogen concentrations seems to be quite possible.

In contrast, other researchers believe that crucial components and infrastructure elements are not hydrogen-tolerant to the extent expected.

A case-by-case examination should be conducted to prove which theory is on the right track.

Modernization of calibration regulations

Hydrogen blending in natural gas pipelines poses a crucial challenge. Even more so for network and gas metering point operators. For them, this is a new stage. A stage where estimating the energy content of the mixed gas at the exit points calls for high metering accuracy and great operational expertise. On that note alone, an adjustment to the philosophy to run and start-up the infrastructure is due.

But, what other change could stand out in sight of operating a ‘hydrogen blended with natural gas’ network?

The modernization of technical and calibration regulations, for sure! This update is an urgent action to moderate the aspects related to quality and monitoring while blending hydrogen. Here are three examples that bring attention to its importance:

1. Heating value

Hydrogen has a calorific value of ≈ 4 kWh/Nm³. Natural gas is ≈ 10 kWh/Nm³.

Hydrogen blended with natural gas creates a mix whose properties divert from those approved in technical regulations.

A change must happen to introduce compliance targets that suit this new mix. Otherwise, wrongful penalizations may occur.

2. Metrology

Measurement equipment and accessories are central to all operations. Hydrogen blending in natural gas pipelines is not an exception.

In July 2020, the Federal Network Agency (BNetzA) stated its support for the adequacy of metrology systems to meet the terms of hydrogen blending. They emphasized that “the measuring equipment, in particular the process gas chromatographs, …would [have to be] completely replaced, as they are currently not capable of or approved for hydrogen measurement.”

Besides, doing the replacements is mandatory for correct billing under calibration law.

3. Billing

Determined energy contents represent the basis for billing in the value chain. All users included.

Since the hydrogen content at each exit point fluctuates depending on the load flows, today’s legal metrology regulations don’t enable decentralized supply to end customers.

Billing methods must adapt to the new modality.

Hydrogen injection and storage

The injection of H2 into the natural gas grid infrastructure has limits. The reason behind it? The differences in chemical composition and fuel properties between H2 and natural gas in the grids. Their mixture could risk connected gas applications — and the network itself — if the final H2 % (vol) is loose. Hence, setting boundaries to prevent harmful impacts applies.

On storage, H2 is only suitable for underground cavern facilities.

Temperature influences

Seasonal dependencies affect the hydrogen blending process. This phenomenon happens in the high-temperature months of summer.

In the summer, the low energy consumption and throughput often come with a reduced flow rate. If this low flow rate is to feed hydrogen only, the mixture with (existing) natural gas won’t be good. Hydrogen bubbles will form. Then, high hydrogen concentrations in the natural gas network appear.

As turns out, watching over the temperature makes a difference in blending efficiency.

Gas flow rate continuity in the network

Natural gas flow in the grid is yet another aspect to watch when blending hydrogen. The significance lies in the impact it can have on the compliance of legal limits.

Since hydrogen’s concentration in the natural gas network is about 10% and, for some applications, it can’t be above 2%, monitoring gas flow rate is essential to decide when and where to feed H2 into the grid.

About that, experience avails that:

- a location with a continuous high gas flow in the network is helpful for electrolyzers

- on the other hand, even small hydrogen amounts in low natural gas flow rates can lead to local exceedance of the permissible limits.

This insight is key for operators. So, they can pick the best location in the grid for H2 injection.

Storage proximity

Always check the spatial proximity with gas storage facilities in advance. Especially when there is a large water electrolyzer with downstream methanation. This is a vital step that can enhance the process.

Final thoughts

Creating a new model for hydrogen transport and distribution while blended with natural gas is an exciting prospect to look forward to in the years ahead. With that, the help of many actors is central to write joint and decentralized frameworks to regulate the rising industry.

A recent win for the cause is the recently confirmed support of the natural gas sector, which feels inspiring and encouraging at this time. A leading example of coming together for a shared aim:

“The making of a sustainable hydrogen economy that can benefit from the well-kept natural gas infrastructure. All in favor of spreading the path of transformation and innovation!”

Still, there’s much work left to do to accomplish goals and targets. So, at this moment, I want to focus on just a couple of spheres:

Operational-technical

Operators must gain an extensive view of this new landscape. After all, their hands are the ones to be in charge of calibrating and manipulating equipment to blend hydrogen into the natural gas grids at ratio. Beyond that, they need to be on top of operational procedures subject to drastic change. Not a surprising fact when aware of the fast swifts in the hydrogen chain according to the type of process: electrolysis, storage, methanation, injection, and end-user conditions.

Political and economic

A few years back, when hydrogen first entered the picture, the idea was to build an entire infrastructure around it. As time passed, the approach of blending hydrogen into the natural gas network really took off as the most affordable solution. Yet, there is a lack of certainty on how far the blending can go. And if an extra effort to build or reclassify dedicated H2 systems is necessary anymore. This latter scenario is more consuming, as it demands more resources to execute. Moving on from this uncertainty phase is crucial. The way to do this is through clear strategies and frameworks. Better yet, they have to be championed by government policies that provide clear insights and guidelines for the future of hydrogen.

Those are my final thoughts on this evolving matter.

Until a next time.

External sources

- Grenzwerte für Wasserstoff (H2) in der Erdgasinfrastruktur

- Zukunft Wasserstoff

- Integration erneuerbaren Stroms in das Erdgasnetz.

- Wasserstoff im Erdgas: Wie viel Klimaschutz bringt H2-ready?

- Wasserstoff

- Herausforderung Wasserstoff – Was Pipeline-Betreiber wissen müssen

- Neues Gas in alten Leitungen – Werkstofffragen

Image Source: © malp (Adobe Stock) & AS-Schneider