Chloride induced stress corrosion cracking (CISCC) in pipelines

The energy sector has passed through various atmospheric and process environmental challenges. How big is the challenge? It depends on the region, application, process media, and industry. It is also not limited to these factors. One of these challenges is Chloride Induced Stress Corrosion Cracking (CISCC).

CISCC is one of the most common reasons for steel deterioration. It attacks austenitic stainless steel components in the petrochemical industry.

Corrosion can lead to catastrophe. It has the potential to discharge toxic substances and stored energy. Austenitic stainless steels are iron-based alloys that contain 19 percent chromium and 9 percent nickel. These steels have high corrosion resistance in most aqueous and atmospheric settings because of passivation by a thin layer of chromium oxide. Humid and wet environments containing chloride ions can cause pitting. It also causes crevice corrosion of austenitic stainless steel components.

Many companies use 300 series stainless steel. It offers excellent resistance to general corrosion. However, even 300 Series stainless steel is susceptible to CISCC.

Chloride corrosion of stainless steel

Stainless steel can donate free chlorine ions to an aqueous solution. Thus, it has the potential for causing failure in stainless steel. Chloride induced corrosion is not like the bulk corrosion seen in rust. It is the exact opposite and does not spread out in an even layer like rust. Instead, pits and crevices form and grow perpendicular to the surface under attack. The corrosion is often severe in some areas, while others may appear untouched. Thicker pipes and tubes do not always last longer than thin ones. They are as susceptible to failure due to chloride-induced corrosion.

A pipeline’s defense against chloride stress corrosion cracking (SCC) depends on the family of stainless steel from which it comes. The austenitic family is more vulnerable than any other. Its resistance relates to the amount of nickel contained in the steel, with most vulnerable austenitic categories having nickel contents ranging from 8 to 10 wt%. Austenitic classes with high molybdenum and nickel contents, such as 904L and alloy 20, have better chloride SCC resistance. Ferritic stainless steels are very resistant to chloride SCC, including Types 430 and 444.

What is stress corrosion cracking in pipelines?

Pitting causes the failure of stainless steel because of perforation. It engenders SCC in pipelines and other applications. The life cycle of the stainless alloy decreases. We assume that corrosion happens in several pits on both sides of the rivet deeps. We also assume that it causes many fatigue cracks. A system failure can occur because of the linkage between any two neighboring cracks. The pits continue to grow until the pipeline ends up with fatigue crack nucleation. It is here that mechanical effects such as stress intensity factor come into play.

What causes stress corrosion cracking?

CISCC requires the presence of:

- Chloride. Saline environments cause CISCC in 300 series stainless steel

- High temperature. Surface temperature >40-60°C is enough to develop CISCC in 300 series stainless steel

- Stress – applied or residual

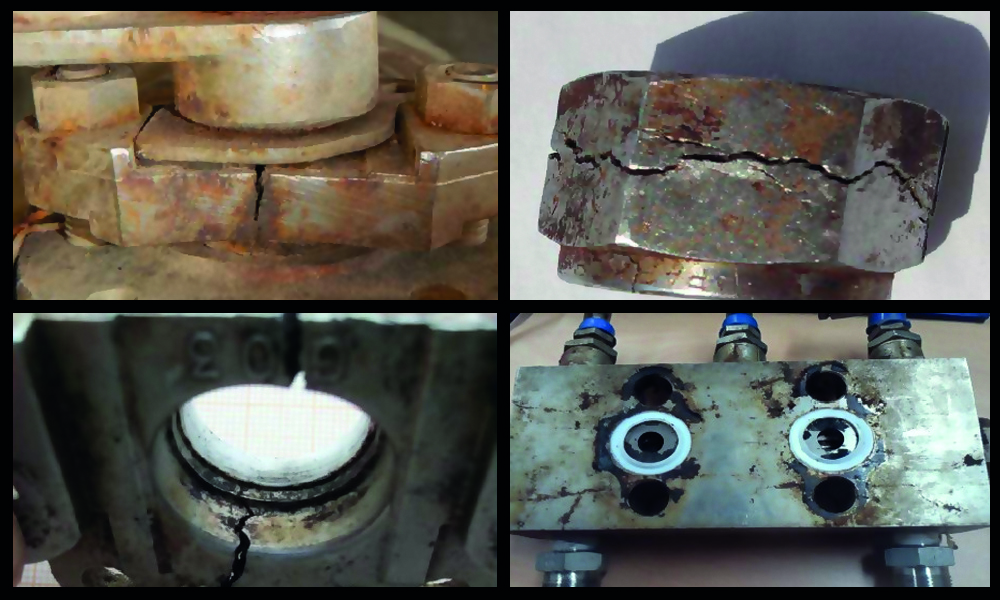

Below are a few examples of cracks due to the use of 300 series stainless steel components. Companies use these components on machines and valves. They also use them on accessories and other equipment in the plant/field. The analysis shows that the cause is CISCC.

How does stress affect corrosion?

The literature does not have a unified mechanism for SCC. Experts have proposed various models, including the following:

- Film rupture model. Stress causes the local rupture of the passive film and sets up an active-passive cell.

- Absorption model. Specific chemical species absorb on the cracked surface and lower the fracture stress.

- Embrittlement model. Hydrogen embrittlement is a significant mechanism of SCC for steels and other alloys.

- Pre-existing active path model. This model uses pre-existing paths, such as grain boundaries. Under this model, one can see the formation of inter-metallics and compounds.

How to detect stress corrosion cracking?

Dye penetrant testing is one of the tools used to detect SCC. It is the most straightforward and effective non-destructive examination technique. Eddy Current Testing is also useful. This type of testing uses purpose-designed probes calibrated on known defects. Penetrant testing does not show the crack size. Eddy Current testing may show it, but the use of this type of testing is limited in this regard. Technicians can also apply ultrasonic flaw detection. They can use it as an automated or manual NDE technique for detecting CISCC.

How to prevent stress corrosion cracking?

One of the solutions to this challenge is the selection of correct material. Technicians also need to select the right sealing elements. Some of the materials that fight CISCC are alloy C-276 and 6Mo. It is common practice in the industry to use alloys for wetted/pressure-retaining parts. Technicians also use it for small components in 300 series stainless steel. This practice is not advisable. The tiny components lodge between other parts, and can corrode and crack. Painting the system with aluminum is also recommended to fight CISCC.

Companies can also reduce the risk of SCC through equipment and plant design. It is especially important to avoid any mechanical tensile stress concentration. This type of stress applies to notches and sharp edges.

(Image Source: olando / Adobe Stock & AS-Schneider)