TA-Luft amendment - What will change for you as a plant planner and plant operator in the area of valves

The Technical Instructions on Air Quality Control or TA-Luft governing Germany’s industrial plants were recently updated. The goal of the TA-Luft is to reduce emissions and improve air quality.

In this article I will give you an overview of the TA-Luft amendment and explain the specificities and requirements applicable to industrial valves. Furthermore, I analyze the changes to the old TA-Luft to identify challenges and solutions.

Plant operators and plant planners can’t miss out on this info to run compliant facilities.

What is the TA-Luft?

The TA-Luft is the central German regulation for the reduction of emissions and immission of air pollutants from plants requiring a permit.

It defines the state of the art for more than 50,000 plants in Germany and provides the authorities with a uniform national instrument for air pollution control, thus leading to greater legal and planning certainty when approving plants.

Overall, TA-Luft helps the authorities and industry to serve and protect the environment.

How are air pollutant regulations classified by TA-Luft?

The TA-Luft splits air pollutant regulations into two sections, immission and emissions.

Immission: Contains the set of regulations to protect the environment and citizens from high pollution levels. For example, a plant’s approval now requires checkups on the effects it will cause on air quality and on sensitive biotopes in its vicinity.

Emissions: Holds the requirements for precautionary measures against harmful effects on the environment. The regulation also:

- Sets the corresponding discharge levels for all relevant air pollutants from plants.

- Covers requirements for new industrial plants and formulates those aimed at existing facilities. After appropriate transitional periods, the requirements must generally be brought up to the state of the art and thus to the emission level of new plants.

Substances and media controlled by TA-Luft

Practically, all air pollutants traced back to industrial plants are regulated. This range of contaminants include:

- Classic mass pollutants such as dust, nitrogen oxides, and sulfur dioxide

- Organic compounds, including dioxins and furans

- Carcinogenic, mutagenic, or reprotoxic substances

The new version is paying extra attention to:

- Extremely hazardous contaminants

- Components requiring urgent reduction for environmental and health protection

- Mercury, ammonia, and carcinogenic substances are on the list

Are there any exceptions to TA-Luft?

Greenhouse gas subject to emissions trading stands out as the only exception.

Which industries are basically affected by the TA-Luft?

Nearly 50,000 plants across Germany are affected by TA-Luft. Among these are included:

- Waste treatment facilities

- Factories in the chemical industry

- Metal production plants

- Cement mills

- Large-scale plants in the food industry and animal husbandry sectors

TA-Luft amendment

As previously shown, TA-Luft has a big influence in industrial operations and planning. Hence, it is vital for the influenced sectors to learn about the new changes prevailing in the current update to the former 2002 edition of the TA-Luft.

When does the TA-Luft amendment come into force?

It took several steps for the TA-Luft amendment to come into force:

- May 28th, 2021: Federal Council generates the requirements

- June 23rd, 2021: German Federal Cabinet approves the new version

- September 14, 2021: Joint Ministerial Gazette publishes the new version

- December 1st, 2021: The legislation comes into force

The amendment transposed several regulations from EU bills into national law. This concerns numerous precautionary requirements contained in implementing decisions of the European Commission on Best Available Techniques (BAT) conclusions based on the Industrial Emissions Directive (Directive 2010/75/EU).

Legal framework backing the TA-Luft amendment

Though it only has legal character in Germany, the new TA-Luft based its latest requirements on:

- Specifications by the European Industrial Emissions Directive

- Especially for valves: ISO 15848-1 standard (often referenced worldwide)

Are new plants obliged to be TA-Luft compliant?

Yes, all new plants must be compliant with the TA-Luft amendment.

Product manufacturers supplying goods to the industries identified above must be TA-Luft compliant. The range of products regulated are valves, pumps, compressors, flange connections, etc.

Note: Packings for valves cannot be designated as TA-Luft-compliant, since the proof for the complete valve (e.g., according to ISO 15848-1) must be provided.

Additions introduced by the TA-Luft amendment

The amendment to the TA-Luft added new regulation measures for:

- Odor pollution caused by plants

- Ammonia and particulate matter emissions from the exhaust air of large-scale livestock installations

In addition, new plants must develop a nature conservation plan just to meet the approval requirements.

After getting familiarized with the TA-Luft’s scope and recent legal framework changes, it’s time to dive into their implications for industrial valves.

TA-Luft amendment and industrial valves

I have analyzed the impact of the TA-Luft amendment on industrial valve systems. Here are the leading findings that may interest plant planners and plant operators.

What has changed for industrial valves?

The main change is in the procedure to perform and review valve compliance tests:

- Old TA-Luft (2002 edition) referred to VDI 2440 for the qualification of valves

- TA-Luft amendment calls for performance verifications according to ISO 15848-1 (November 2015 edition)

Check out the TA-Luft side-to-side comparisons table below to expand on the modifications applicable to performance verification.

Topic | Old TA-Luft | TA-Luft amendment |

|---|---|---|

Issue date | July 2002 | December 2021 |

Proof of tightness | Carried out using VDI 2440 | According to procedure ISO 15848-1 (November 2015 edition) |

Chapter 5.2.6.4 | Shut-off devices For the sealing of stem feedthroughs of shut-off or control devices, such as valves or gate valves, the following are required: • High-quality sealed metallic bellows with downstream safety stuffing boxes or equivalent sealing systems shall be used. Sealing systems are to be regarded as equivalent if the temperature-specific leakage rates are complied with in the verification procedure in accordance with VDI 2440 (November 2000 edition). | Shut-off or control elements From 01.12. 2025, shut-off or control devices used, such as valves, gate valves or ball valves, shall meet: • Leakage rate LB (≤ 10-4 mg/s∙m) related to the stem circumference at pressures up to ≤ 40 bar and design temperatures ≤ 200 °C • Leakage rate LC (≤ 10-2 mg/s∙m) related to the stem circumference at pressures up to ≤ 40 bar and design temperatures > 200 °C • For pressures > 40 bar and design temperatures ≤ 200 °C, the leakage rate LC (≤ 10-2 mg/s∙m) related to the stem circumference shall be fulfilled and shall be reached at > 200 °C. Seals of spindle bushings designed as high-quality sealed metallic bellows with downstream safety stuffing boxes meet the requirements of the leakage rate LB without separate verification. Otherwise, DIN EN ISO 15848-1 or other proven equivalent test or measurement methods (e.g., helium leakage test or the purge gas method) must be used to verify the specific leakage rate of the sealing system, for testing as well as its evaluation and qualification. Permanent tightness requirements for the testing and maintenance of the sealing systems must be specified in the management instructions. |

Upgrading the proof of tightness procedure from VDI 2440 (old TA-Luft) to ISO 15848-1 (TA-Luft amendment) is a pleasant change, especially since the specifications of VDI 2230 allowed a broad scope for interpretation.

Valves tested according to the old specs were not comparable to each other. Moreover, meaningful endurance measures, such as the number of mechanical or thermal cycles, were not defined. Only the sealing system of the stem feedthrough was considered, excluding the body seal. Anyone who wanted to know exactly how the valve tested always had to look at the test report.

The situation is different with ISO 15848-1:

How to approach proof of compliance with the new TA-Luft requirements for valves?

The best way is through the current VDMA/VCI guideline containing the valve requirements found in the new TA-Luft (Chapter 5.2.6.4: Shut-off or control devices).

The team behind the guideline is a working group sponsored by:

- The German Engineering Federation (VDMA), and

- the German Chemical Industry Association (VCI).

Members of the working group are:

- Plant operators

- Valve manufacturers

- Testing institutes

- Testing organizations

All parts are well regarded in their industry.

They also work together to find a consensus on non-regulated points.

Main requirements of the TA-Luft amendment

( 1 ) Bellows sealed valves

Valves with high-quality sealed metallic bellows and downstream safety stuffing boxes still fulfill the TA-Luft.

No other verification is necessary for them.

( 2 ) Qualification of the valves

Qualification is now carried out under ISO 15848-1 (November 2015 edition). The test sequence is precisely specified here, and the tested valves can be directly compared with each other.

TA-Luft also allows other proven equivalent tests or measurement methods. However, these are not recommended, as the verification turns out to be difficult and leads to major discussions.

( 3 ) Tightness class

ISO 15848-1 distinguishes between the three tightness classes A, B, and C, yet, it doesn’t define which class must be achieved. Thus, TA-Luft specifies the required tightness class as a function of pressure and temperature:

Temperature range | p ≤ 40 bar | p > 40 bar |

|---|---|---|

T ≤ 200 °C | LB (BH) | LC (CH) |

T > 200 °C | LC (CH) | LC (CH) (to be aimed at) |

Note: The leakage rate according to TA-Luft is given in LB or LC and is identical to the leakage classes BH and CH according to ISO 15848-1.

If methane is used as test gas, the measured concentration value must be converted into the unit mbar * l/s.

Important observations about tightness class

From the table above, a TA-Luft specs gap can be appreciated.

Let’s exemplify it through a PN 40 valve with a maximum permissible temperature of 225°C.

At first glance, the tightness class to fulfill is LC since the temperature is > 200°C. Now, what if the operator wants to use this same valve in a pipeline set with a max temperature of +150°C?

Under this scenario, achieving tightness class LB is necessary. Hence the conflict.

There are two possibilities to address this operational example:

- If the valve reaches class LB during the test at 225°C, this is sufficient.

- If the valve only achieves the class LC in the test at 225°C, the tightness class LB must be proven in a further test at 200°C.

A similar approach can be extrapolated to PN 63 valves. If the valve only achieves class LC in the test at 63 bar, the leak tightness class LB must be verified in a further test at 40 bar at the corresponding temperature.

Currently, this method is the best way to universally ensure the use of TA-Luft compliant valves as per the amendment.

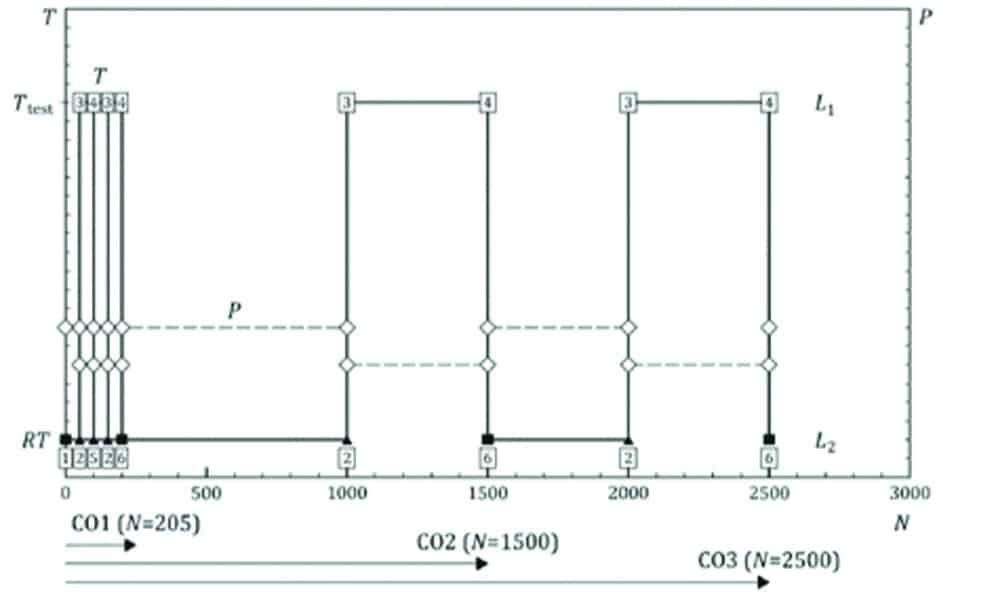

( 4 ) Strength class

ISO 15848-1 distinguishes between 3 strength classes:

- CO1 to CO3 for isolating valves

- CC1 to CC3 for control valves

| Valve type | Endurance class | |||||

|---|---|---|---|---|---|---|

| CO1 / CC1 | CO2 / CC2 | CO3 / CC3 | ||||

| Number of cycles | ||||||

| mechanical | thermal | mechanical | thermal | mechanical | thermal | |

| Isolation valve | 205 | 2 | 1,500 | 3 | 2,500 | 4 |

| Control valve | 20,000 | 2 | 60,000 | 3 | 100,000 | 4 |

Classification of isolating valves according to mechanical cycles

For shut-off valves, the test cycle is performed in correlation to these parameters:

Ttest

L1

L2

N

P

Test temperature in °C

Measurement of stem seal leakage

Measurement of leakage of body seal

Number of mechanical cycles

Pressure of the test medium

Important observations about endurance class

- TA-Luft itself does not define endurance class requirements.

- What to do to ensure permanent tightness conditions?

- Check the management instructions! They outline the requirements for the testing and maintenance of sealing systems.

- If management instructions demand considerable effort on your side, just go to the VDMA/VCI guideline. It will recommend aiming for the highest endurance class (CO3) without tightening the packing gland (SSA0).

- By the way, when consulting the VDMA/VCI guideline, don’t forget to confirm it’s up to date with the latest agreements!

- What happens when valves reach a class?

- Valves reaching the CO3 class can join the maintenance-free and “tight for life” status.

- Valves that get to class CO1 or CO2 or had to face packing retightening during the test need a maintenance concept note from the manufacturer.

- Still, some aspects remain up for discussion.

- For instance, can a small and rarely used valve (think of a pressure gauge valve) be labeled maintenance-free when class CO1 is reached without packing readjustment

- Undoubtedly, this is a thought-provoking analysis for all plant operators. Especially when factoring in that CO3 valves are pricier than CO1 valves.

Test performance and validity of TA-Luft after amendment

On test performance:

- TA-Luft does not specify who should perform the tests on the valves.

- VDMA/VCI guideline recommends all testing be carried out by a specialized laboratory accredited in DIN EN ISO/IEC 17025, or the testing having a certification from an independent body is ideal too.

- Choosing the right lab for the job is key to having security and confidence in the testing procedures and outcomes.

About test validity:

- The proof of TA-Luft conformity according to DIN EN ISO 15848-1 is valid for an unlimited period as long as the design is not significantly changed when using the same materials.

Do existing valves get special treatment?

Under certain circumstances, existing shut-off or control valves may continue to be operated:

Service | Specifications | Operational continuity status |

|---|---|---|

Shut-off or control devices for liquid organic substances | • Compliance of 5.2.6(a) without meeting any of the characteristics specified in (b) through (d)

• Non-compliance with the requirements specified in 5.2.6.4(1) through (3) | May continue to be operated until replaced by new shut-off or control devices. |

• Compliance of 5.2.6 letters a to d

• Meet the requirements pursuant to 5.2.6.4 paragraphs 1 and 2 of old TA Luft (July 24, 2002) | May continue to be operated until they are replaced by new shut-off or control devices. | |

Which TA-Luft version is more rigorous?

At first glance, the new TA-Luft allows larger leakage rates (about a power-of-ten higher). However, this notion is up for challenge when analyzing the leakage rate basis specified on each standard:

- ISO 15848-1, the leakage rate depends on the shaft diameter

- VDI 2440, the calculation is dependent on the mean gasket circumference

Since a circumference is larger than the diameter by a factor of 3.14 (pi) and the gasket has a larger diameter than the stem, it’s fair to declare the assessment isn’t as linear as originally conveyed.

Let’s test out what happens when comparing a shut-off valve with the following characteristics:

- Stem/spindle diameter: 12 mm (ISO 15848-1)

- Average seal circumference: 50 mm (VDI 2440)

Temperature range | Permissible leakage rate in mbar l / s | ||

|---|---|---|---|

TA-Luft 2021 / ISO 15848-1 ≤ 40bar | TA-Luft 2021 / ISO 15848-1 > 40bar | TA-Luft 2002 / VDI 2440 | |

<= 200°C / 250°C | 2,14 × 10-5 | 2,14 × 10-3 | 5,00 × 10-6 |

>200°C / 250°C | 2,14 × 10-3 | 2,14 × 10-3 to be aimed at | 5,00 × 10-4 |

As seen above, based on permissible leakage rates, the results state the old TA-Luft (in conjunction with VDI 2440) is the stricter standard. The difference gets particularly pronounced at conditions above 40 bar and <200°C.

Yet, it’s worthy of reminding that aligned to ISO 15848-1, the new TA-Luft now demands:

- Test for body seals

- Run-through of two temperature cycles, at least

These new additions must be factored in when assessing the original question: Which TA-Luft is stricter?

Ultimately, final rating on the new TA-Luft will depend on how the tests are carried out and the number of mechanical and thermal cycles performed.

My final thoughts on the TA-Luft amendment

The TA-Luft amendment is here to align air pollutants emissions from industrial plants to the new targets set by the EU to decrease environmental and health hazard.

Plant operators and plant planners across several industries have to gear up their processes to comply with the new notions.

Regarding industrial valves, overall, the new changes introduce by ISO 15848-1 (November 2015 edition) seem favorable to overcome past issues in valve testing:

- The old specs left a wide room open for interpretation

- Valves couldn’t be compared to each other

- The number of mechanical and thermal cycles were not well defined

- To know exactly how the valve was tested, people always had to look at the test report

- Only the sealing system of the stem feedthrough was factored in (housing seals not included).

Now:

- Tested valves can be divided into performance classes according to tightness, temperature, pressure, and strength

- The entire valve is classified (not only the stem seal)