Understanding the need for additional training to close the skills gap in the oil and gas industry

January 24 is celebrated as the International Day of Education. It highlights the role of education in promoting world peace and development. This day emphasizes the need for equitable, quality learning for all. And it also carries an important message for the industry in general:

In a rapidly changing technological environment, it is important for companies to acquire new skills and knowledge through continuous training of their personnel. Additional training enables organizations to keep up with new trends in the industry. It also helps them close the gap between available and required skills.

Companies that invest in the development of their staff are able to better respond to new opportunities and challenges. These can arise from changes in technology, regulations or standards.

This blog article discusses why employee training is important for the oil and gas industry. It also shows what causes the existing skills gap, how this gap can be bridged and the challenges of retraining employees. It emphasizes the importance of ongoing training for engineers, maintenance personnel & operators in the industry with a view to taking advantage of the latest technological advancements.

Importance of training in oil and gas industry

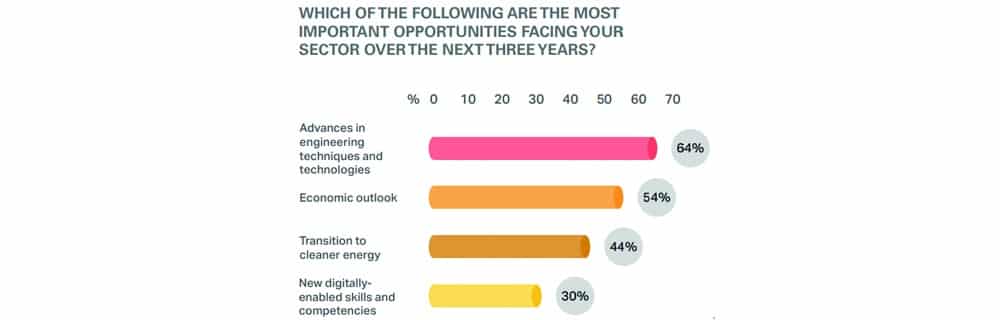

In an industry survey, published in the Global Energy Talent Index (GETI) Report 2021, respondents were asked to identify the most important opportunities in the oil and gas sector over the next three years.

64% of the respondents selected ‘advances in engineering techniques and technologies’ as one of the most important opportunity in the industry.

Other popularly selected opportunities included ‘transition to cleaner energy’ (44%) and ‘new digitally-enabled skills and competencies’ (30%).

Source: GETI Report 2021, Page 15, https://www.getireport.com/reports/2021/

In the same survey, respondents were also asked ‘how can employers build resilience into the business?’ According to 41% of the respondents, the answer lies in increased training and mentorship.

The survey results show that in order to take advantage of the available opportunities, companies in the sector must invest in additional training of their staff.

How do these skill gaps actually arise in the oil and gas industry?

Skills gap is defined as the difference between the skills an employee has and the skills actually required to do the job well. The skills gap is considered to be especially wide by many experts in the oil and gas industry for the following reasons:

Unique training challenges

The regulatory framework, to which the oil and gas industry must comply, is in a state of constant evolution.

Businesses must carefully navigate regulations that require them to bear responsibility for the actions of their upstream suppliers, and the safety of extraction sites they build and operate. Compliance with new regulations mandates retraining of an aging workforce to address environmental concerns and safety hazards.

Advent of new technologies

New technologies such as artificial intelligence, data analytics, and the Internet of Things are transforming industries around the world; the oil and gas industry is no exception.

In order to cut production costs, these technologies are being introduced into exploration, refining, and distribution activities. These new technologies cannot be internalized through workers who do not possess the requisite skills. In order to bridge the skills gap, workers must either be replaced or retrained.

Critical skills acquired through experience are not passed on

Ideally, experienced employees should pass all the skills they have acquired on the job to a new generation.

In practice, however, this is difficult to achieve as both generations of employees are preoccupied with performing their routine tasks. In addition, some skills require formal training sessions to be taught and learned.

Misconceptions about the oil and gas Industry amongst the younger generation

The environmental issues surrounding the oil and gas industry and its fluctuating boom-to-bust nature have attached a stigma to industry jobs that is making it difficult to attract future talent.

The millennials perceive careers in the industry as harmful to society, unstable, dirty and even dangerous. 62% of young Americans, born between 1998 and 2001, consider a career in oil and gas as unappealing, according to a survey of 1,200 young Americans released by Ernst & Young In 2017.

The reluctance of the younger generations means that it is comparatively harder for the oil and gas industry to attract workers skilled in new technologies.

How to bridge the skills gap in the oil and gas sector?

The skills gap in the oil and gas industry is a major hurdle for organizations that want to fully exploit the emerging opportunities. These opportunities promise increased efficiency and profitability provided the skills gap can be bridged. There are several approaches to bridging the skills gap.

- Expect existing employees to pick up skills on the job

- Outsource business functions to external contractors

- Bring in new temporary/permanent staff with relevant skills

- Retrain existing employees

Expecting existing employees to acquire the necessary skills on the job is a time-consuming and risky proposition. While this approach may initially appear to save some costs, it can lead to production/financial losses or even fatal accidents during the learning process.

Outsourcing business functions is not always a practical option especially when dealing with critical tasks in a production environment.

Bringing in new people with the necessary skills can solve the problem but these new hires need to be trained in other company procedures and need time to settle into the new environment.

Retraining and upskilling of existing employees is the key to bridging the skills gap. It is the quickest solution to acquiring the skills necessary to take advantage of new opportunities and dealing with new challenges.

In the oil and gas industry, a vast majority of employees already require training at the start of their careers due to the prerequisite of a specialized skillset. There is a need to recognize employee training as an ongoing process where employers identify the needed skills and retrain suitable employees to bridge the gap.

Benefits of investing in employee training

Training of employees to bridge the skills gap improves employee performance. This could mean increased productivity, lower costs, greater regulatory compliance and enhanced worker safety for the organization.

Employee training also increases employee engagement. Employee engagement refers to the level of dedication and enthusiasm a worker feels toward their job.

The time and resources dedicated by the organization towards training make an employee feel valued; this can lead to a steep rise in employee engagement.

Retirement of older and more experienced employees can create a talent gap in an organization. Training young employees provides them career advancement opportunities while ensuring competent replacement options for retiring experts.

Challenges to reskilling and upskilling

Reskilling or upskilling workers can present different challenges depending on whether the retraining exercise is carried out internally or outsourced to an external organization.

Internal training can be difficult due to non-availability of people who can serve as trainers or lack of learning material and relevant content.

In external training, it can be difficult to find a program that aligns well with the needs of the business. External training also requires greater commitment of time and resources from both the employer and the employee as it may require travelling and staying away from the job during the training period.

Onsite training, through a specialized external organization, that can customize the training program to meet the needs of the employer, is an ideal solution to these challenges.

The oil and gas sector is at a critical juncture where the role of technology in ensuring profitability and regulatory compliance is increasing rapidly. In addition to investing in high tech hardware, companies must also invest in their workforce to successfully leverage these technologies and to achieve their broader goals.

INFO-BOX

AS-Schneider can help you bridge the oil and gas industry skills gap

AS-Schneider offers various training courses for engineers, maintenance staff, and operations personnel in the fields of instrumentation and process technology. AS-Schneider trainers are engineers and technicians with years of hands-on experience in the industry.

The training program is especially useful for plant operators. Engineering personnel responsible for the planning and maintenance of oil and gas facilities can also benefit from the training program.

Staff training with AS-Schneider offers the following benefits:

On-site training

Off-site training can be expensive, not only in terms of travelling time and costs but also due to loss in productivity from absence of key personnel. AS-Schneider offers on-site training through its world-wide network of local experts. In addition, the company offers online courses in the form of webinars to educate the staff directly at their workplace. On-site training also provides a confidential environment for discussion of sensitive issues.

Scheduling flexibility

AS-Schneider can schedule training sessions at the time and place convenient to the customer. Courses can also be scheduled on weekends to minimize the disruption of the internal workflow. Training experts are available via telephone and email to discuss the client’s specific requirements.

Content customization

Critical issues and challenges facing a company can vary depending on the nature of the process, and plant design. The previous training and skill level of personnel can also vary from one company to another. AS-Schneider coordinates with the client to design a training program that is most useful for the staff. Only content that is directly relevant to the client’s objectives is included in the course.

Sustained support

AS-Schneider provides a permanent contact person to its clients. The designated person coordinates with the customer to develop a strong sense of the client’s work environment and technical needs. The training material is designed and adapted accordingly. In addition, the permanent contact person provides support after training by answering any queries and by organizing follow-up sessions.

Training courses

AS-Schneider offers training in several product and application areas including valves, manifolds and their broad applications. Specific products for which training is offered include ball valves, double block & bleed (DBB) ball valves, and close coupled installations. The courses are customized for different application areas as well as for different target groups and individual knowledge levels.

The courses enable plant personnel to make better equipment selection decisions based on the total cost of ownership rather than just the equipment cost. This involves consideration of productivity, safety, and regulatory requirements in addition to the installation location and process medium.

Typical training programs include:

- Double Block & Bleed (DBB) Ball Valves

- Close Coupled Installation (D Series, Process to Instrument Valves)

- Ball Valves

- Customized online courses

- Customized on-site training courses

How it works

The process starts with a conversation with an AS-Schneider trainer who evaluates the needs of the client and works out a customized training program. A convenient training schedule is then agreed upon for on-site training of key personnel.

The training involves display of product samples and drawings for clear illustration.

A feedback discussion is held after program completion to evaluate what has been achieved or implemented on the basis of the training. This discussion leads to identification of further challenges that can be tackled together.

The training is not intended to be a one-time event, but part of a long-term sustained cooperation. AS-Schneider aims to leverage its long-term experience in the field of instrumentation and process technology for the success of its clients.

Image Source: © haled, Kings Access, pichitstocker (Adobe Stock) & AS-Schneider