Metal seated ball valves for extreme operation conditions

Our customers are often faced with the challenge of determining exactly the right valve/manifold application for extreme operating conditions. For process plants I can recommend the use of metal seated ball valves if abrasive products, high temperatures and pressures are present. Extreme operating conditions with temperatures up to 450 °C and pressures up to 420 bar require a special sealing technology for ball valves. Standard soft seated ball valves simply aren’t ready for this kind of requirements. Their plastic seats would fail.

Does tightness contradict a smooth actuating torque?

In order to be able to give an answer, I have to explain briefly the functional principle of a ball valve: A relatively low contact force is sufficient to ensure the tightness of the ball to the ball seat, as the contact force is automatically increased with increasing pressure due to the design principle. However, in order to ensure the tightness of the ball seats towards the body, high forces are required for high pressures in order to compress the graphite seal accordingly. These forces are often applied by a screw connector or when assembling the ball valve body (for example a three piece body).

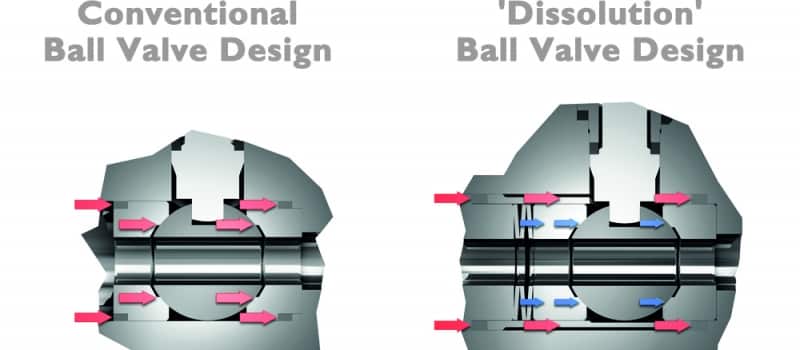

In a conventional design, the compression force for the graphite seals on the ball seat towards the body is applied directly via the ball, which also increases the contact pressure of the ball seat on the ball as the seal is compressed. This increased contact force has a negative effect on the actuating torque. The ball runs very heavy. Therefore many manufacturers limit their metal seated ball valves to a max. allowable pressure of 100 bar. – because that is the limit that still permits actuation of the valve.

If the applied force is reduced, actuation becomes easier, but then the compression of the graphite seal on the seat retainer is not sufficient to seal up to 420 bar reliably. Leakage occurs around the ball seat.

So what now? This problem has not let go of my development team. We started looking for a solution and developed the ‘Dissolution’ ball valve design. The patented design offers optimum distribution of forces and loads in the ball valve, so that they only occur where they are actually needed. This means that the ball valve can be actuated easily even under high pressures up to 420 bar.

How it works – ‘Dissolution’ ball valve design

The forces needed to maintain the tightness between ball seat and valve body are only directed onto the corresponding graphite seal rings. The ball is only spring-loaded, which ensure a low, defined, minimum pressure off the balls on the ball seat. The operating torque can thus be significantly reduced, allowing the operator to operate the ball valve easily. At the same time, this construction offers maximum tightness and long service life.

Image Source: © AS-Schneider